One noticeable trend at the latest PACK EXPO Las Vegas was the need for machine builders to focus on ease of use. As industry struggles to get the technical skills necessary on staff to operate equipment, the need increases not only for machines that perform at advanced levels but that do so with intuitive interfaces, requiring minimal know-how.

“Our customers are telling us that the capability of the technology is all for nothing if it cannot be learned by a non-skilled operator really easily and in a short period of time, and then to be confident in really operating the equipment to deliver on its promise of automation,” says Marco Azzaretti, director of marketing for Key Technology a member of the Duravant family of operating companies. Customers added that they didn’t need the equipment to get any better if it was going to make it more complex.

This was an eye opener for Key Technology, which introduced its Compass family of optical sorters specifically to address these demands. The new sorters are engineered to streamline the sorting process with a focus on ease of use, consistent accuracy in removing foreign materials and product defects, and improving the overall quality management of food products.

Compass offers high sort accuracy and a compelling return on investment with significantly simpler operation than traditional food sorting systems. They are designed to handle a variety of food products, including processed and frozen vegetables, fruits, nuts, leafy greens, potato chips, and confections. With its advanced sensors, lighting technology, and the new Next sort engine, Compass systems can accurately separate a range of foreign materials from food products, ensuring the delivery of the quality grade expected by customers.

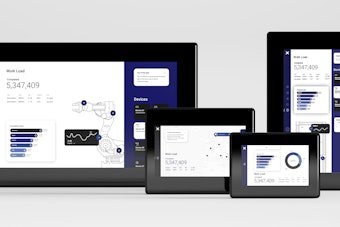

The user interface is highly intuitive, resembling smart device app navigation, which allows operators with no technical background to quickly master the sorter. The Compass sorter also includes Key Discovery, a data analytics and reporting software that transforms the sorter into an IIoT-connected device. This provides processors with valuable insights into their line operations, further aiding in quality management and process optimization.

Key Technology offers the Compass sorters in various configurations to meet the specific needs of each customer. The company has initially introduced chute-fed models, with belt-fed variants to follow. The sorters can be installed at different stages of the food processing line, from the start to ensure incoming product quality, to the end for final product safety checks before packaging.

The development of Compass also involved external expertise. The company collaborated with Ergosign, a German firm specializing in human-machine interface (HMI) design. “We realized that the same skillset that it takes in developing the machine is not the same skillset that allows you to make the machine also easy to use on the part of the operator,” Azzaretti says. This partnership has resulted in a user interface that is not only functional but also approachable for operators of varying technical backgrounds.

“Frankly, it’s not easy to make things easy to use,” comments Jack Lee, group president for food sorting and handling solutions at Durvant. “Easy to use actually takes a huge amount of insight, a lot of effort.” This effort is evident in the Compass system’s design, which aims to make automation accessible and manageable for all users.