Sustainability is the new watchword for a huge and growing band of consumers, according to a June 2022 report from PMMI titled “Achieving Packaging Sustainability.” The ongoing green movement presents an opportunity for businesses facing increasing competitive and economic pressures to gain value in competitive advantage as they respond to environmental concerns and the pressures of resource scarcity, population growth, and higher and more varied consumer expectations.

Perhaps unfairly, the packaging industry is seen as one of the worst environmental offenders, the PMMI report states. At a recent Top to Top event held in Florida, PMMI hosted roundtables with participants from across the packaging value chain. Participants indicated that it’s not just CPGs that should be implementing sustainability strategies. OEMs also have a crucial part to play in energy savings. In fact, a current hot topic in Europe is a carbon footprint rating for each new machine.

| Download the 2022 report, "Achieving Packaging Sustainability," from PMMI. |

Overall, the message from participants at the Top to Top meeting is that it’s all about the collaboration between CPGs, material suppliers, and OEMs as they plan ahead for the next generation of packaging materials.

However, while consumers continue to seek sustainable products, they may not be willing to pay the price, according to a recent report from market research firm AMC Global and OpinionRoute, a company that provides insights into process management. These survey results say that many consumers want sustainably produced and sourced products, but price remains the top consideration when making purchasing decisions. According to AMC Global, consumers believe these products are more expensive than their mainstream counterparts, and recent inflation and price increases are making affordability a key concern. In addition, a high percentage of respondents say it is hard to tell which brands are sustainable and which are not.

While 43% of people believe it is worth it to pay more for sustainable products, 66% say they can’t afford to do so due to recent price increases across the board.

| Learn more about AMC's "Importance of Sustainability" report. |

While consumers often look to retailers and product packaging to guide them on sustainability, the winners of ProFood World’s annual Sustainability Excellence in Manufacturing Awards are focused on reducing greenhouse gas emissions, electricity, and water, as well as food waste and materials management. Following are the six 2021 Program and Project Category winners.

FIRST PLACE | Program Category

No-cost Project Yields $1 Million Payback for Conagra Brands

Conagra Brands’ Oakdale, Calif., facility created a cross-functional team that made excellent progress in reducing food waste.Conagra Brands

Conagra Brands’ Oakdale, Calif., facility created a cross-functional team that made excellent progress in reducing food waste.Conagra Brands

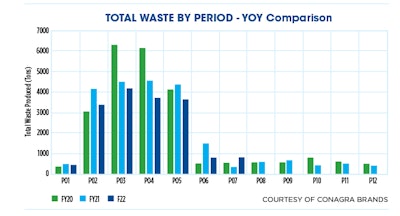

The Oakdale, Calif., Conagra Brands facility makes Hunt’s and Ro-Tel brands, and other food products. Over the past year, the facility’s cross-functional team made excellent progress in reducing food waste. The team implemented a comprehensive plan and problem-solving program throughout 2021 to eliminate ingredient loss points for both jalapeños and tomatoes. The program addressed three causes of jalapeño waste (spoiled ingredients, batch planning, and fill controls) and two processes for tomato waste (peelers and fillers). As a result, the plant utilized 650,000 lb of jalapeño and 13.8 million lb of tomato raw ingredients compared to 2020, which reduced the site’s solid waste footprint by about 10%.

“By manufacturing food ingredients more efficiently, we are using utilities more efficiently,” says Kate Pitschka, director of supply chain sustainability, pointing to Scope 1 and 2 greenhouse gas (GHG) emissions. “We are also moving a significant portion of the site’s food waste up in the recovery hierarchy from animal feed and compost.”

The plant is located in a high water-risk region, and eliminating some of the organic load being sent to wastewater operations is reducing some stress on the region’s water cycle. By eliminating food waste, the facility is reducing the amount of Scope 3 GHG emissions (EPA WARM and Biogenic) that the food waste would create downstream.

Teams were established during March to May 2021, project scopes were defined within one to two months, and specific projects were implemented between July and October 2021, resulting in a 4% jalapeño yield improvement and a 1.8% tomato yield improvement.

“Savings were strictly through better use of available equipment resources and process improvements, with limited costs,” explains Pitschka.

The Oakdale cross-functional team delivered a $471,000 jalapeño yield loss reduction (spoiled ingredients, under net weight rejections, and overfill) and a $730,000 tomato yield loss reduction. These calculations do not include the energy cost savings associated with treating the food waste going to wastewater, nor the hauling costs of the solid waste.

The team discovered that of the 650,000 lb of jalapeño waste, 236,300 lb were from spoiled jalapeño ingredients, resulting in a 4% year-over-year yield improvement and an elimination of all spoiled ingredients in 2021.

Food waste is greatly reduced at Conagra Brands’ Oakdale facility through better use of equipment and process improvements.Conagra Brands

Food waste is greatly reduced at Conagra Brands’ Oakdale facility through better use of equipment and process improvements.Conagra Brands

In 115 days, 6,900 tons of recovered tomato losses were achieved, representing a 1.8% yield loss improvement year over year. This tomato waste was going through a wastewater treatment system where solids are separated and sent to animal feed. “It is difficult to fully quantify the full comparison because of increasing production and some of this existing waste weight stayed in the water cycle, but the amount of solid waste produced by the site decreased significantly during these specific months,” states Shelley Huskey, environmental manager. In the end, about 10% of the site’s total solid waste was eliminated from the prior year.

Programs like this have been implemented at other Conagra facilities, but the Oakdale team had to use problem-solving concepts and apply them to their lines, equipment, and circumstances. “More specifically, the foundational knowledge comes from the Conagra Performance System principles,” says Huskey.

Any manufacturing facility could implement the concepts of this type of problem solving, but like the Oakdale team, they will need to adjust it to meet their site-specific losses. “Often in a manufacturing setting, it is difficult to get past the reactionary mindset because of all the urgent issues that tend to arise, but it is crucial to shift to a proactive mindset in order to address problems like these,” Huskey adds.

SECOND PLACE | Program Category

Bob’s Red Mill Focuses on Wasted Food Rescue and Materials Management

Bob’s Red Mill employees intercepted product from the waste stream and were trained to identify donatable items.Bob's Red Mill

Bob’s Red Mill employees intercepted product from the waste stream and were trained to identify donatable items.Bob's Red Mill

Committed to creating a sustainable future while inspiring joy with wholesome foods, Bob’s Red Mill Natural Products fosters nourishing a healthy planet. One of the company’s main goals is reducing food loss from farm to fork through wasted food rescue. “By rescuing unavoidable scrap, we are avoiding climate emissions that would occur downstream,” says Julia Person, sustainability manager for Bob’s Red Mill. “We donate food to local non-profits, as well as send inedible product to animal feed. Another way we are furthering this work is by joining the Pacific Coast Food Waste Commitment to collectively work with other food businesses to cut food waste in half by 2030.”

The Milwaukie, Ore.-based company’s materials management focus extends beyond food waste to refuse, reduce, reuse, and recycle the maximum possible material flow at the plant, with a goal to reach zero waste. At Bob’s Red Mill, wasted food rescue and materials management programs have helped reduce operations costs for the employee-owned company and have a positive impact, both environmentally and socially, in the local community.

“In 2021, we kept over 385,000 lb of edible food from going to waste, upcycled 2,293 tons as animal feed instead of landfill or compost waste, and recycled more than 1,600 tons of materials such as cardboard, plastic, metal, and wood,” states Person. “Our food donations help provide healthy, wholesome food to those in need in our surrounding community.” Through donations to the Oregon Food Bank network, Bob’s Red Mill provided 161,521 meals to those experiencing hunger in 2021. It donated rescued food to four main organizations in the Portland, Ore., metro area—Oregon Food Bank, The Canby Center, Sunshine Division, and Gleaners of Clackamas County.

In 2021, Bob’s Red Mill’s recycling diversion rate, or rate of materials diverted from the landfill, was 90.8%; 4,201 tons of materials were recycled or upcycled. “While we would practice the food waste rescue and recycling programs regardless of ROI, the programs were able to generate net revenue in 2021,” explains Person. “This revenue figure is after waste disposal costs are subtracted.”

The company saw costs for manpower and waste disposal, but generated value for baled cardboard, baled plastic film, reused pallets, recycled metal, and upcycled feed.

The project timeline was approximately two months to collect data from a variety of sources and an additional two months to onboard a new commodity recycler and feed upcycling company.

In addition, uncalculated savings for this program included reduced carbon emissions related to food waste not reaching the landfill or compost facility.

“In total with upcycling, reuse, and recycling efforts, we diverted 4,201 tons (8,402,599 lb) in 2021,” Person says. “Knowing that our local community needs nutritious food, we connected with non-profits to get our rescued food donated. In addition, in 2021, we examined our feed upcycling program and found opportunities for improvement by working with a new partner to ensure the maximum amount of feed is upcycled.”

With the start of its official sustainability program in 2021, Bob’s Red Mill measured its baseline and collected information on all materials flow. Person says having this data lets the company know what it is not yet diverting from the landfill and focus on improvements.

Bob’s Red Mill set up processes with machine operators to intercept product from the waste stream and trained the material handling team to identify donatable items. For scrap product going to the animal feed stream, Person recommends thoroughly vetting any sustainability partners to ensure that material flow is timely, and communication is strong.

THIRD PLACE | Program Category

Pizza Yield Improvement Project at Conagra Brands Comes With No Cost

Conagra Brands’ Troy, Ohio, team has strong foundational knowledge on the Conagra Performance System principles and effectively applied it to a pizza bakery line.Conagra Brands

Conagra Brands’ Troy, Ohio, team has strong foundational knowledge on the Conagra Performance System principles and effectively applied it to a pizza bakery line.Conagra Brands

Conagra Brands’ Troy, Ohio, team implemented a comprehensive continuous improvement program on the site’s bakery line when running pizza, and have set up new process and operating standards, organization, and line planning. Ongoing efforts are expected to deliver more than $325,000 in cost savings by reducing yield loss by 13.4% and eliminating 267,000 lb of meat, cheese, and breading waste.

“Every opportunity to manufacture food more efficiently will allow us to use water and energy resources [Scope 1 and 2 GHG] more efficiently,” says Kate Pitschka, director of supply chain sustainability. “However, they are not directly quantified in this submission. Also, by eliminating food waste, we reduce the amount of Scope 3 GHG emissions [EPA WARM] that the food waste would create downstream.”

Meat toppings process and planning analysis took six months and concluded in August 2021; cheese process and planning improvements took five months and concluded in November 2021; extra toppings and cheese reuse took one month to implement in September 2021; and over a two-month period, employees’ continuous improvement skills were developed, beginning in November 2021.

The reduction of the weight average per case is forecasted to deliver annualized savings of more than $325,000.

“Programs similar to this have been implemented at other Conagra facilities, but the Troy team is one of the most effective,” Pitschka explains. “They have strong foundational knowledge on the Conagra Performance System principles and applied it to their bakery line, equipment, and staffing circumstances.”

“Any manufacturing facility can implement the problem-solving tools used in our continuous improvement program, but it would take a long time to develop the continuous improvement culture like we have at the Troy facility,” says Plant Manager Jeff Erwin. “For example, it would take another facility with a less-developed culture many months instead of just the two months it took us,” he adds. The Troy facility demonstrated that it is worth investing in the development of all team members.

FIRST PLACE | Project Category

Conagra Facility Saves Nearly 9 Million Gallons of Water

Staff at Conagra Brands’ Irapuato, Mexico, facility implemented a water and chemical savings project that saved the facility close to $50,000.Conagra Brands

Staff at Conagra Brands’ Irapuato, Mexico, facility implemented a water and chemical savings project that saved the facility close to $50,000.Conagra Brands

The main objective of the project at Conagra Brands’ Irapuato, Mexico, plant was the reduction of water consumption. In this project, two specific situations were considered:

- Identification of water leaks and improvements in the sweet corn process and canning process equipment.

- Completing sanitation more efficiently on various lines to reduce the consumption of cleaning chemicals, resulting in greater production line availability. Also, some of the sweet corn equipment required a redesign to eliminate or make more efficient use of water.

Reducing water consumption is a benefit for the entire community since the plant is located in an area with limited water availability. By improving the operating conditions of its wastewater treatment facility and discharge parameters, the water can be reused for farmland irrigation.

“The corn/cannery production improvements were completed over seven months, finishing in September 2022, and the sanitation improvements were completed from April 2021 to May 2021,” says Fernando Alcántar Gómez, EHS manager. “Both projects resulted in an 8% reduction in water use per production year over year, with ROI in less than a month.”

The project returned more than 10 times its cost, saved nearly 9 million gal of water, and reduced chemical usage by 2,680 gal.

“With a cross-functional team and advice from prior facility projects, the Irapuato site was able to implement these projects with ease and maintain the quality of our food products,” states Alcántar.

SECOND PLACE | Project Category

Switch to Plastic Combos at Smithfield Foods Is an Environmental Winner

At Smithfield Foods’ Milan, Mo., facility, the switch from cardboard to reusable plastic combos is expected to save $1.3 million over the next five years.Smithfield Foods

At Smithfield Foods’ Milan, Mo., facility, the switch from cardboard to reusable plastic combos is expected to save $1.3 million over the next five years.Smithfield Foods

Early in 2021, Smithfield Foods’ Milan, Mo., plant started sending out hams for further processing, transporting them in cardboard combos. The facility quickly realized it could save money and reduce cardboard usage by using reusable plastic combos.

Less than 30 days into the project, the plant ordered 720 plastic reusable combos. On average, the Milan facility ships 100 combos of hams per day. “Although 720 plastic combos are not enough to replace every cardboard combo we ship, it will reward us with a 50% reduction in cardboard usage,” says Wes Maulsby, wastewater operator at the Milan facility.

The combo project’s goal included:

- Reducing GHG emissions—Cardboard savings can be directly related to the release of methane, a GHG, as it breaks down in a landfill. Per ton released, methane will contribute to global warming at a pace more than that of carbon dioxide.

- Reducing water usage—Using less cardboard creates less demand and reduces manufacturing water usage.

- Reducing energy—Fuel sources to manufacture cardboard are no longer needed.

- Reducing global warming—Deforestation is a huge contributor to global warming. The facility can save 17 trees per ton of corrugated cardboard savings, and every eight pallets saved will yield one saved tree.

- Reducing landfill—For every ton of cardboard savings, landfill area can be cut by 9 yd3.

The project was completed in the first quarter of 2021, when the Milan plant shipped the first hams for further processing. In February 2021, the facility received its first load of plastic reusable combos and, in March 2021, shipped the first load of hams in reusable combos.

The Milan facility expects to save more than $1.3 million over the next five years employing reusable combos. “We use this mindset of reusable combos vs. cardboard combos whenever applicable,” explains Maulsby.

But not all applications will accommodate the conversion to plastic combos. “When it can be used, it is very cost-effective for this company and beneficial to our environment,” Maulsby states.

Pitfalls may include logistics, he adds. “We have more than enough combos to ship all of our product on a seven-day rotation, if we receive our plastic combos back within seven days. Logistics is key to keeping our plastic combos in circulation. If we can receive all combos back within a timely manner, we can easily increase cardboard savings.”

THIRD PLACE | Project Category

Conagra Brands’ Blast Cell Air Optimization Project Reaches ROI in Less Than a Year

The staff at Conagra Brands’ Marshall, Mo., plant discovered and repaired sources of significant energy waste in the freezing operation.Conagra Brands

The staff at Conagra Brands’ Marshall, Mo., plant discovered and repaired sources of significant energy waste in the freezing operation.Conagra Brands

Degradation of freezer blast cells was resulting in improper airflow and inefficiency of the blast cell function at Conagra Brands’ Marshall, Mo., facility. Repairs were made to air segregation, and baffle design was changed to reduce potential damage from the forklift loading process.

“Baffles were added at the back of each rack column in the blast cells to force the airflow through the product pallets to improve the heat transfer of the freezer,” explains Scottie McKenzie, plant engineering manager. “This reduces the freeze time, lowers electricity consumption, and increases plant capacity.”

The project will reduce the plant’s electricity consumption by 5.7% and reduce the plant’s Scope 2 GHG footprint by almost 1,300 metric tons. “Efficiency projects like this will be an important piece of the entire company’s science-based target,” he adds.

In September 2021, a freezer evaluation uncovered inefficiencies in the blast cells. Contractors installed baffles inside the blast cells in November 2021, and performance monitoring occurred in December 2021. The project paid for itself in less than one year.

At the Marshall facility, product requiring freezing is estimated at 500,000 lb/day. Now the plant has seen a 10% reduction in freeze time, a 5.7% total site electricity reduction, and an overall reduction in kWh/lb usage. The result is a yearly savings of more than $200,000.

“This project would be worth looking into for any cold storage facility, specifically where blast cells are loaded using forklifts,” says McKenzie. Identifying potential damage could be a way to uncover sources of significant energy waste. “Training to specifically not damage the entryway would be something that could be avoided at other facilities,” he adds.

Meet the Winners at PACK EXPO Las Vegas

Register now at www.packexpointernational.com.

ProFood World wants to hear about your current sustainability projects. The submission deadline and eligibility requirements for the 2022 Sustainability Excellence in Manufacturing Awards will be announced this fall on ProFoodWorld.com.