This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The solution enables fast and enhanced design and fabrication of high-performance molded fiber tooling in as quickly as two weeks compared to four to six weeks experienced by customers using traditional methods. Combined with HP's new tooling production service, the end-to-end solution delivers greater production efficiencies via increased production up time, reduced maintenance, and mass customization capabilities.

HP is partnering closely with Pulp Moulding Dies Inc. (PMD) to deliver the next-generation of durable, lighter, faster, and easier to use tools. HP is also working with packaging solutions companies such as Veritiv, who works with customers from design concept to completion, to accelerate the adoption of more innovative and sustainable molded fiber packaging designs for customers across industries including food service, consumer product, medical, and industrial markets. Initial customers already using HP's new solution include Fiber Innovation, Pacific Pulp Molding Inc., Pulp Moulded Products Inc. (PMP), and Western Pulp Products Co.

“As businesses around the world, including HP, make the commitment to plastic-free packaging initiatives, the molded fiber industry is leading the way with its production of renewable, recycled and natural fiber for products and packaging,” said Mariona Company, Global Head of Molded Fiber Solutions, HP Inc. “HP operates with sustainable impact at the core of our business and we are proud to bring breakthrough HP innovation and world-class services to manufacturers of molded fiber products. Powerful design capabilities and the advanced production capabilities of our new HP solution are opening up entirely new packaging possibilities for the industry.”

HP's new Molded Fiber Advanced Tooling Solution eliminates the time consuming and intensive manual fabrication involved in the traditional molded fiber tooling manufacturing process. Leveraging proprietary HP innovations in digital manufacturing software and data intelligence, including a new digital design platform along with HP's industry-leading, industrial 3D printing technology, the solution offers a digitally-designed experience enabling more efficient, optimized design and replacing the need for handcrafted screens, CNC machining, and manually drilled form tools.

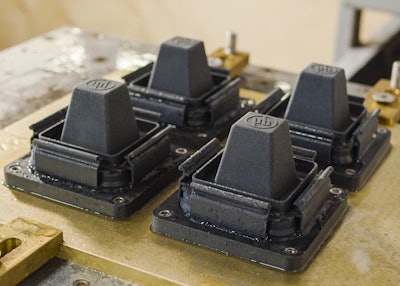

In addition to the sustainable qualities of molded fiber packaging, HP's tooling is made from vegetable castor oil, a 100% renewable raw material. HP also enables 70% reuse of surplus material in the production of its tools. The material's strength and flexibility results in tools with optimal mechanical properties and consistent performance. Improvements in overall equipment effectiveness (OEE) and enhanced flow in HP's tooling solution will enable manufacturers to produce more parts using less fiber for more sustainable production processes.

HP has partnered closely with PMD, based in Ajax, Ontario, a leader in the molded fiber tooling industry for more than 40 years, to advance molded fiber tooling capabilities for PMD customers around the world producing a variety of packaging. PMD's deep expertise in molded fiber tooling along with the advanced design, data, software, and production capabilities of HP's digital manufacturing platform has led to advances in custom screens, previously impossible complex packaging geometries, and improvements in the overall dewatering process. Through its collaboration with HP, PMD has been able to produce molded fiber tools 10-20 times lighter than conventional tools.

"We're all in with HP's new solution," said Troy Mutton, President, PMD. "We've used every machine and tool under the sun and they are all heavy, massive dinosaurs with major limitations compared to HP's innovative 3D printing solution. I've been ready to take advantage of the time savings and unlimited design opportunities provided by 3D printing for more than two decades, but until now, no technology has met our needs for quality and consistency like we are seeing from HP. HP has delivered a true production technology that meets our needs and will help us continue to lead the industry."