This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

LOG Pharma Primary Packaging, a global provider of packaging solutions for the pharmaceutical industry, offers drug manufacturers a complete, integrated packaging solution. By producing both bottles and caps at the same facility, LOG is ensuring unmatched compatibility, reducing waste, and delivering superior confidence in packaging integrity.

Traditionally, pharmaceutical companies source drug bottles and containers from one supplier and caps and closures from another. This approach often leads to mismatched components, increased material waste, and unnecessary frustration. Seeking a streamlined solution, several pharmaceutical companies approached LOG to request a comprehensive packaging option where both bottles and caps are sourced from a single, trusted supplier.

In response, LOG has expanded its capabilities to provide fully integrated packaging solutions. Pharmaceutical manufacturers can now obtain bottles and perfectly fitting caps from a single production site, ensuring optimal compatibility and compliance with strict regulatory standards, including ISO 8317:2015.

“After being approached by several clients who were already purchasing our bottles and asking if we could also supply the caps, we decided to take full responsibility for the entire production process,” said Shaul Bassi, Chief Executive Officer of LOG Pharma Primary Packaging. “We made significant investments in state-of-the-art machinery to produce caps that precisely match our bottles, giving our customers the reliability and confidence they need.”

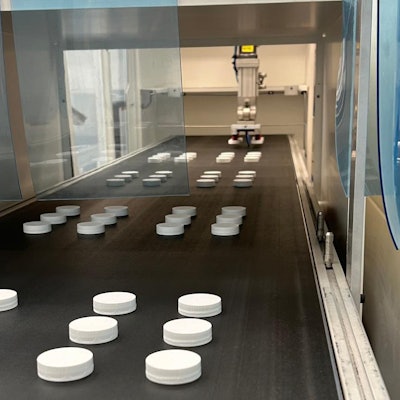

As part of this strategic expansion, LOG has deployed two new dedicated injection molding machines, capable of producing over 100 million bottle caps a year. This high-capacity production ensures a consistent supply of top-quality packaging components, supporting the stringent needs of the pharmaceutical industry.

One leading international pharmaceutical company is already benefiting from LOG’s fully integrated packaging line, reinforcing the company’s role as a trusted and innovative partner in the industry.