Air Products

Allentown, PA 18195

Faster freeze times, increased throughput, improved product quality

Freeze your way to higher throughput, better taste, and more with Freshline® liquid nitrogen freezing systems from Air Products. Explore the advantages of food grade liquid nitrogen freezing and chilling. Food grade liquid nitrogen freezing has many advantages over mechanical freezing and chilling processes. It’s faster. More flexible. Takes up less space. And helps food products maintain moisture (preventing weight loss from dehydration), quality, texture, color and flavor. In addition, Air Products’ Freshline systems can help improve your productivity, lower your costs and maximize your returns. All of which can help make you more competitive in a very competitive market.

Put your food to the test at our state-of-the-art in-house food testing lab, or we'll come to your facility with our mobile food lab. This allows for testing on full-scale production equipment for freezing, chilling, packaging, and cryogenic grinding to:• Evaluate product quality and process improvements by using Nitrogen, CO2 or other food-grade gases• Identify proper equipment for production needs• Determine economics of using cryogenic gases in your process• Identify cost savings opportunities by evaluating gas usage and equipment efficiency

Freshline Food Freezing/Chilling Gases and Equipment

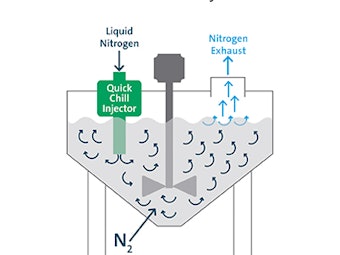

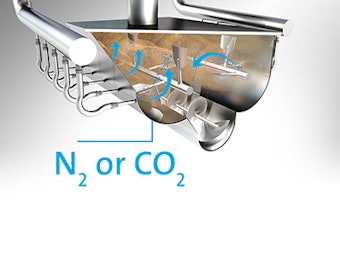

Air Products’ Freshline® solutions offer food processors high-purity food-grade gases (N2 & CO2) and equipment to chill or freeze a wide variety of foods. Select equipment highlights includes: Freshline MP Tunnel Freezer – Designed with efficiency and hygiene in mind, it uses unmatched heat transfer capability to achieve cryogenic temperatures throughout the entire length of the tunnel. Freshline Spiral Freezer providing efficient, continuous freezing/ chilling to a broad range of meat/poultry products in a small footprint at high production rates. Freshline® LIN/CO2 Injector Systems - A tailor-made temperature control system that uses liquid nitrogen or carbon dioxide to deliver rapid, precise temperature control to a blender or mixer/grinder, enabling food manufacturers to optimize processing speed and product quality. The new Freshline® QuickChill™ Injector can be easily fitted to new or existing kettles and vessels to help food processors reduce chilling times and increase throughput of a variety of liquid products, including sauces, gravies and marinades.

The benefits of these cryogenic systems include faster freeze times, increased throughput, improved product quality and more. We also offer gaseous solutions including controlled atmosphere stunning, wastewater treatment, modified atmosphere packaging (MAP) and inerting.

With food laboratories located in the U.S., Europe, and Asia, the company can test a customer’s product on commercial-scale equipment to determine the feasibility of using cryogenic freezing or chilling for their specific process.

For more information about Air Products’ complete portfolio of Freshline® solutions for food processing, call 800-654-4567 (outside of the U.S. 610-706-4730) or visit www.airproducts.com/food.