Munson Machinery Company, Inc.

Utica, New York 13502-5750

Leaders in Mixing, Blending and Size Reduction Machinery Since 1823

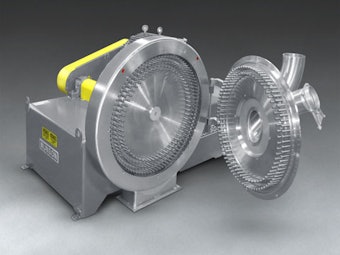

Munson offers the industry's widest selection of equipment for mixing and blending of bulk food products (with or without liquid additions) including: Rotary Batch Mixers, Ribbon/Paddle/Plow Blenders, Cylindrical Plow Blenders, Vee-Cone Blenders, Fluidized Bed Mixers, Rotary Continuous Mixers, and Variable Intensity Blenders. For size reduction of spices, herbs, nuts, dates, roots, grains, beans and other bulk food products, Munson manufactures Lump Breakers, Pin Mills, Attrition Mills, Screen Classifying Cutters, Knife Cutters, Shredders, and Hammer Mills. For solids separation, the MUNSIFTER™ Centrifugal Sifter can sift and scalp bulk food materials at high rates with virtually no product degradation.

Munson Machinery's experienced sales engineers will answer any questions or requests for additional information on our products and services.

The exceptionally broad selection of full size equipment in Munson’s test laboratory allows side-by-side testing of your actual material, and documents precisely how effective — or ineffective — any given machine would be at meeting your specific performance requirements. This assists customers in specifying a machine at no cost or obligation—and takes the risk out of purchasing bulk food processing machinery.

Munson Machinery Company is a leading manufacturer of mixing, blending, size reduction and separation equipment serving the food, dairy, coffee/tea, nutraceutical and hemp industries.

Munson Machinery offers the industry's widest selection of mixing and blending equipment for dry bulk food products (with or without liquid additions) and food products in solids-laden liquid or paste form, including Rotary Batch Mixers, Ribbon/Paddle/Plow Blenders, Vee-Cone Blenders, Fluidized Bed Mixers, Rotary Continuous Mixers and Variable Intensity Blenders. Also size reduction equipment including Screen Classifying Cutters, Pin Mills, Rotary Lump Breakers, Attrition Mills, Hammer Mills and Shredders. For solids separation, the Munson’s Centrifugal Sifter can sift and scalp bulk food materials at high rates with virtually no product degradation.

Munson equipment is available constructed of #304 or #316 stainless steel and finished to food, USDA dairy or pharmaceutical standards, with optional CIP systems.

Established in 1823, Munson offers unparalleled experience in solving the most challenging problems encountered by customers through two centuries, continuously improving equipment performance to a level unmatched by any comparable manufacturer worldwide.