IFS, a global enterprise applications company, has released a primary research study on how the Internet of Things (IoT) affects readiness for digital transformation in industrial companies. According to survey of 200 IoT decision makers at industrial companies in North America, only 16 percent of respondents consume IoT data in enterprise resource planning (ERP) software. That means 84 percent of industrial companies face a disconnect between data from connected devices and strategic decision making and operations, limiting the digital transformation potential of IoT.

The study posed questions about companies’ degree of IoT sophistication. The study also explores how well their enterprise resource planning (ERP), enterprise asset management (EAM) or field service management (FSM) software prepares them for digital transformation and to consume IoT data.

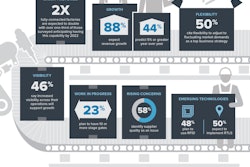

Respondents were divided into groups including IoT Leaders and IoT Laggards, depending on how well their enterprise software prepared them to consume IoT data—as well as Digital Transformation Leaders and Digital Transformation Laggards depending on how well their enterprise software prepared them for digital transformation.

- The two Leaders groups overlapped, with 88 percent of Digital Transformation Leaders also qualifying as IoT Leaders, suggesting IoT is a technology that underpins the loose concept of digital transformation.

- Digital Transformation Leaders made more complete use of IoT data than Digital Transformation Laggards; Leaders are almost three times as likely to use IoT data for corporate business intelligence or to monitor performance against service level agreements.

- Digital Transformation Leaders were more likely than Digital Transformation Laggards to be able to access IoT data in applications used beyond the plant floor. They were more than four times as likely to have access to IoT data in enterprise asset management software, twice as likely than Digital Transformation Laggards to be able to access IoT data in high-value asset performance management software, and almost twice as likely to be able to be able to use IoT data in ERP.

- The data suggests a real need for more IoT-enabled enterprise applications designed to put data from networks of connected devices into the context of the business.

In reviewing the findings, IFS Chief Technology Officer for North America, Rick Veague, commented, “Are your planning and maintenance systems robust enough to make real time decisions using IoT-sourced data? Many are facing the reality of having to answer ‘no.’ We have seen examples of companies coming to us because their incumbent software is not able to administer and use IoT data to achieve the gains they want to realize.”

“The study results suggest that the most common use case for IoT in these industrial settings is condition-based maintenance. The benefits go beyond operational improvements and maintenance cost avoidance,” said Ralph Rio, vice president of enterprise software at ARC Advisory Group. “It increases uptime that provides additional capacity for increased revenue. It also avoids unplanned downtime which interrupts production schedules causing missed shipment dates and customer satisfaction issues. When married to demand and scheduling systems in ERP, IoT becomes a revenue-enhancement tool improving the top line.”

Resources:

Download the Industrial IoT and Digital Transformation Study.