This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

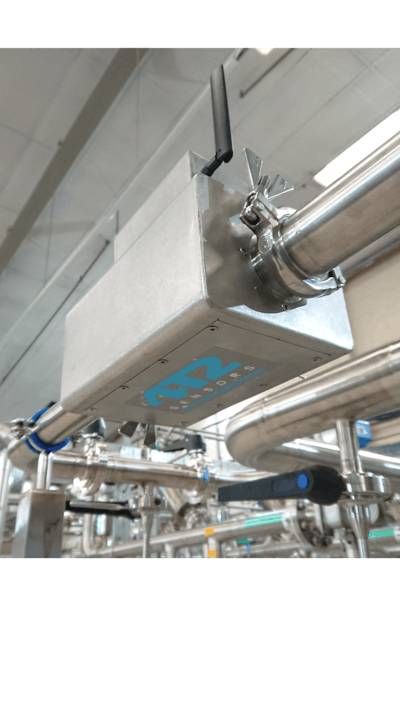

Specifically designed for the dynamic nature of clean-in-place (CIP) processes, the 4T2 Sensors CIPSense impedance sensor allows for real-time high-resolution measurements, making it possible to accurately detect concentrations, contamination, and mixtures of fluids, and optimizes CIP recipes by reducing cycle times for caustic, acid, or treated water phases.

The CIPSense sensor has patented sensing technology, which generates an electrical fingerprint of the fluid in the pipe. Building on this technology, the sensor provides up to 180 hr of additional production time and over 1,000m3 of annual water savings per process line.

The standalone system seamlessly integrates with any SCADA system, ensuring easy scalability.