Though Ethernet has been taking hold in a growing number of industries and applications, fieldbus is far from obsolete. Many thousands of legacy fieldbus networks will continue to be relied on in the years ahead. The cost to rip and replace these networks is a daunting one for any manufacturer. Besides that, legacy fieldbus networks have some unique advantages—such as ensuring intrinsic safety in hazardous environments—that many industrial Ethernet systems are not yet able to provide.

“Ethernet forms the backbone of any modern industrial network, but there are still places that some Ethernet systems cannot go,” explains Michael Bowne, executive director of Profibus and Profinet International (PI) in North America. “Four-wire Ethernet today still carries too much voltage and current on the wire to guarantee intrinsic safety. Currently, we’re working hard to develop a reliable, two-wire, IEEE-approved solution known as Advanced Physical Layer (APL) for hazardous environments.”

PI is investing in new technologies such as APL to help turn concepts like Industry 4.0 and the Industrial Internet of Things (IIoT) into a reality. The goal of APL is to bring Ethernet down to field-level instruments in hazardous areas. Taking process industries into the future requires a new network standard to transfer process data using standard Ethernet and IP-based technologies.

“Ethernet in the field level will make digitalization for process industries a reality,” Bowne says. “Ethernet adds its universality and bandwidth to existing field device installations.”

Current and voltage will be limited to provide an intrinsically safe system for Zones 0 and 1 / Div. 1, Bowne explains. The physical connection will be a rugged two-wire connection with power over the same two-wire cable. APL is expected to be able to exceed the 100m limit currently imposed on common 100Base-TX Ethernet networks.“Although work is progressing, APL is still a few years out,” Bowne adds.

There are currently two flavors of Profibus—DP for factory applications and PA for process automation. A number of hybrid industries, such as food and beverage, combine both systems. Though they follow the same protocol, the two versions exist on different physical layers in the network stack.

One of the reasons for continued viability of legacy fieldbus networks is the growing incorporation of diagnostic tools and graphic interfaces that enable faster troubleshooting than traditional analog systems. “Downtime is extremely costly, particularly in process automation, and these diagnostic advances help companies significantly reduce costs and production losses without major capital investments,” Bowne says.

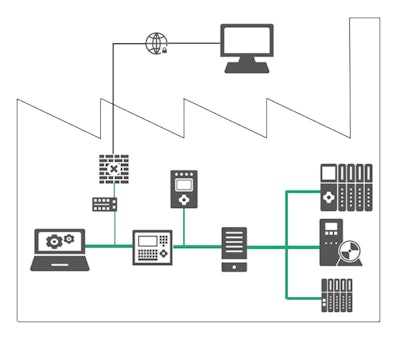

Though new factory installations typically incorporate Profinet, networks installed 10-15 years ago often employ a gateway Profibus and Profinet. “This enables companies to accomplish a piece-wise migration as needed,” Bowne explains. “By installing a modern PLC for the system, for example, they can also leverage the benefits of more insight into their data or higher process speeds and throughput without significant changes to the legacy fieldbus network.”

New industries for legacy networks

EtherCAT, a fieldbus that sends data via Ethernet, is seeing advances in adoption for different applications. “The semiconductor industry, for example, is moving rapidly to EtherCAT because it provides a stronger backbone, more communication bandwidth and greater speed,” says Bob Trask, the North American representative of the EtherCAT Technology Group (ETG). Other industries that have transitioned to EtherCAT include automotive, medical and biomedical device manufacturing, as well as entertainment, humanoid robotics and many advanced motion applications, he says.

The emerging Time-Sensitive Networking (TSN) standard, which provides real-time capabilities in IEEE 802 networks, is one area where EtherCAT is improving communications. “Using EtherCAT at the machine level and for interconnecting machines with TSN bridges creates a state-of-the-art industrial Ethernet network architecture,” Trask says. “Some complex machines, however, will still require an enhanced communication infrastructure. Integrating EtherCAT segments into a TSN network will combine the benefits of both technologies without requiring any changes to EtherCAT slaves. This adaptation, known as stream adaptation, is done by software at the EtherCAT master side. The TSN bridges will be able to route the EtherCAT frame with no modification to the bridge.”

The initial TSN design was intended for streaming large amounts of audio and video data to numerous end stations in real time and is now being applied to a wide range of factory and process automation applications for real-time data flow, improving the determinism of frame transmission in network traffic without losses due to congestion.

While these changes apply in the switching world, they do not change some of the shortcomings of traditional Ethernet networks, such as their lack of efficiency with small data amounts per node as well as their flexible, yet time-consuming and complex forwarding procedures. For ETG, the goal is rather to use TSN as backbone technology in complex machines, in combination with EtherCAT segments.

“Using TSN with EtherCAT, which does not employ TCP, could be a grand unifier,” Trask says, “because EtherCAT can talk easily with legacy network devices, vision and motion systems, providing a bridge to legacy technology so you don’t have to rip and replace. It provides a path to keep legacy systems working for maybe the next 20 years.”

There’s no push to usher out the serial communications that industry has relied on for decades to provide the basic, simple communications approach that people are comfortable with and have the training and hardware to manage, according to Sree Potluri, I/O application specialist for Beckhoff Automation.

“EtherCAT has a lot of built-in diagnostics that make it easy to collect operations data,” she says. “But the newer products also use fewer wires, reducing costs and making it easier to access the increased data everyone wants today.”

EtherCAT P is one example of this growing ecosystem. It combines communication and power into one cable, simplifying the connection of field devices and reducing the cost of industrial networks.

Another example of these advances is a series of ELX EtherCAT terminals from Beckhoff with intrinsically safe I/Os and compact design, enabling direct connection of field devices located in hazardous areas classified as Zones 0, 1 and 2. The terminals seamlessly combine industrial automation and process technology, including all the benefits of integrated and comprehensive diagnostics from the EtherCAT system, facilitating the implementation of barrier-free solutions across hazardous areas up to Zone 0/20.

Staying with what they know

Though changes in the economic environment invariably force technology changes, just as they did in the oil and gas industry when prices declined, HART and Foundation Fieldbus continue to dominate networks in the process industries. “HART is big in the U.S., which favors 4-20 [mA] communications, but they love Foundation Fieldbus in developing industrial countries like in the Middle East and India,” explains Talon Petty, marketing and business development manager for FieldComm Group. “These two legacy networks still represent the vast majority of process automation installations around the world. While the major benefit of Ethernet is speed, few process automation applications require response times in milliseconds, and those that do are in the realm of 250 ms—easily within the limits of well-engineered fieldbus segments.”

To help companies manage the increasing amount of data from intelligent devices, five of the major technology foundations—FieldComm Group (a combination of the former Fieldbus Foundation and HART Communication Foundation), FDT Group, OPC Foundation and PI—have spent the past decade developing a single technology for the management of information from devices throughout all areas of a plant. Called Field Device Integration (FDI), it promises a common set of development tools and a single path to rationalize Electronic Device Description Language (EDDL) and Field Device Tool (FDT) to improve standardization, transparency and, ultimately, cost.

“FDI is not a protocol; it simply structures data in a standardized way such that the data can be understood and sent across various systems in the enterprise. It also incorporates OPC UA, so it has built-in technology that IT personnel are familiar with—making integration easier,” Petty says. “It will enable a smooth transition and provide robust communications for companies that need absolute data access reliability. It will also be less expensive to manage while making it easier to maintain legacy systems.”

Although the FDI technology is still in its infancy, change and adoption are being driven by industries facing pain points in digitalization of their facilities, Petty adds.

Increased connectivity

DeviceNet, which is supported by the ODVA trade organization, is moving from installations focused on “islands of automation” to a more connected factory approach, according to Katherine Voss, who was the association’s president at the time of this interview. Al Beydoun is the new president of ODVA.

“DeviceNet, like EtherNet/IP, utilizes a producer-consumer approach to network communication. Producer-consumer increases network efficiency and performance by optimizing the amount of message traffic on the network,” Voss explains. “DeviceNet has a flexible approach to network architecture freed from the typical constraints in scheduled networks driven by deterministic message delivery. That’s the reason it’s widely used currently for real-time control applications in which millisecond update rates and jitter (with respect to message delivery times) are sufficient.”

Because it’s based on CAN, a low-cost legacy fieldbus widely used in automotive modules for engine control, supporters of DeviceNet see it as a cost-effective way to connect devices not yet connected to the Industrial Internet. Recognizing this potential, ODVA has established a technical working group aimed at the application of DeviceNet to previously unconnected devices through simplified connection and configuration schemes.

“By extending DeviceNet to more types of devices,” Voss says, “users will be able both to preserve their investment in DeviceNet and to leverage seamless connectivity with EtherNet/IP via ODVA’s Common Industrial Protocol, or CIP. Users will be provided with the business benefit of cost-competitive connectivity today for devices previously not connected, as well as systems engineered for the future that can evolve in step with the Internet of Things as the costs of Ethernet continue to decline.”

A willingness to adapt to incremental technology changes in legacy fieldbus networks in order to improve troubleshooting, data access and ease of maintenance will continue to help industries extend the lifespan of their investments in these backbones of automation. Though neither Ethernet nor legacy systems have all the answers, technology suppliers and networking industry groups are working on paths to the future that don’t ignore the needs or customer preferences of the present.