Paxton Products, an ITW Company

Cincinnati, OH 45242

With over 50 years of industry expertise, Paxton Products is the preferred solution for drying, blow off, and air rinsing solutions. Paxton systems maximize performance by coupling Paxton's PX-series blowers with custom engineered air delivery devices.

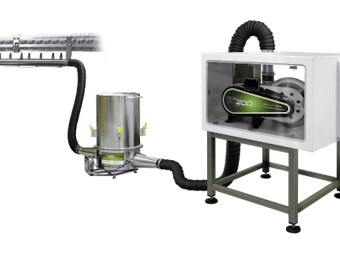

Paxton Products manufactures high efficiency centrifugal air blowers and custom-engineered, pneumatic air delivery devices used for drying, air rinsing, and blow off, in order to improve product quality through better cleaning, rinsing, labeling, marking, and coding. Paxton's Air Delivery Devices, such as our high efficiency Air Knives, are custom-engineered to maximize and improve the quality of drying, blow off, and cleaning of products and surfaces. Our team configures the air delivery device specifically for your unique application - sizing air knives, nozzles, and manifolds for peak efficiency. Available in both aluminum and 304 stainless steel, Paxton’s Air Knives and Knife Systems are designed to give maximum efficiency for high velocity drying and blow off applications. These systems feature a continuous, uninterrupted air slot design that gives uniform air coverage over the targeted area. Because of this, you’re able to significantly reduce the amount of product quality rejects for your business.Coupled with Paxton’s high efficiency centrifugal blowers and air delivery devices, Paxton’s Ionizing Rinsing Systems remove particulates, dust, and contaminants using powerful ionization. The Ionizing Rinsing System provides static control and static elimination so that dirt and dust don’t adhere to surfaces, and then blasts contaminants away using a Paxton PX-series centrifugal blower.For drying, Paxton’s patented PowerDry Drying System sets the standard for a complete, power drying and blow off air system that can used for a wide variety of cans, bottles, jars, and pouches. By incorporating Paxton’s PX-series centrifugal blower, the PowerDry System lowers energy costs by as much as 80% through reduced compressed air usage in bottling, canning, and other packaging operations.Click here to see the full line up of products from Paxton Products.

Paxton Products has an industry-leading, three-year warranty:

Paxton Products (“Paxton”), a business unit of ITW Air Management, guarantees its standard PX-Series, AT-Series and XT-Series blowers, including the XT-300 PowerDry blower, against defects in the materials and workmanship for the 3-year Warranty period in accordance with the terms herein. The product must be installed and operated in accordance with the manufacturing specifications and the installation & maintenance instructions provided by Paxton using Paxton-provided replacement filters, belts and idler assemblies (“Maintenance Accessories”) for the warranty to apply. Proof of purchase of Paxton Maintenance Accessories at the prescribed frequency is required. Motors are warranted through Paxton for 24-36 months under the terms provided by the respective motor manufacturer’s warranty only. Click here to read the full warranty terms.

Paxton’s Air Delivery Devices and Systems are custom engineered to maximize performance and drying efficiency. Because of this, proper installation and maintenance of your Paxton Products system are critical to system performance. Paxton Products’ installation components have been engineered to minimize pressure drop between the centrifugal blower and the air delivery devices, to maximize performance while providing ease of installation. For maintenance, Paxton’s maintenance components are made to exacting specifications, to minimize maintenance costs while ensuring the longevity of your Paxton Blower. Be sure to use genuine Paxton parts to maintain the three-year warranty on your blower. Click here to learn more about Paxton’s installation and maintenance products.

Design and manufacturing of drying, blow off, and air rinsing systems and devices using ultra high efficiency centrifugal blowers, custom-engineered air knives, and other air delivery devices.

For over 60 years, Paxton Products has led the industry with its innovation and design of high efficiency centrifugal blowers used within drying and blow off systems for the manufacturing industry. Paxton Products has its roots in the development of the first high-performance supercharger in 1957. This same technology was used by Paxton Products to create the first centrifugal blower for commercial and industrial applications in the 1970s. This blower utilizes the same high-performance, energy-efficient air delivery technology used in the supercharger and was driven by an electric motor and pulley system - producing significant amounts of air flow with minimal energy usage.

Paxton Products has continued to lead the industry in blower innovation throughout the years, culminating in the introduction of the most efficient 10–20 hp blowers in the world in 2016: Paxton’s PX-Series ultra-high efficiency centrifugal blowers. In 2019, Paxton Products launched the 3–7.5 hp PX-series blowers, improving efficiencies for these smaller, lower horsepower models - making the Paxton Products' line ultra-efficient.

Paxton Products not only offers superior, sustainable products, but also provides unrivaled engineering expertise and an industry-best, three year warranty, compared to competitors' 1-year warranty. Within the 60+ years of operation, Paxton Products has gained industry expertise to make us the preferred solution for drying and blow off applications around the globe.