This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Global Drain Technologies (GDT), a manufacturer of drainage systems, is pleased to announce the launch of its new Circular Catch Basin for the 10,000 Series FoodSafe Slot Drain. Designed specifically for the food and beverage industries, this addition to GDT's FoodSafe product line offers cleaning efficiency and increased water flow, catering to the hygiene requirements of food production facilities.

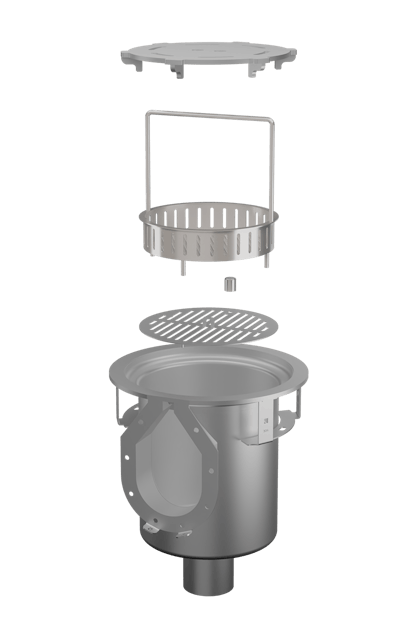

The new Circular Catch Basin is a key feature of the 10,000 Series FoodSafe Slot Drain. Constructed from T304 or T316 stainless steel, this basin offers resistance to corrosion, ensuring durability in most environments. Unlike traditional square basins, the circular design eliminates corner edges, which improves both cleaning efficiency and water flow. This design is advantageous in industries where maintaining a hygienic environment is critical, such as meat processing, seafood packaging, and dairy production.

The 10,000 Series FoodSafe Slot Drain also features a slotted linear trench opening that facilitates efficient drainage while preventing clogging. Available in multiple slot sizes, including 1/2", 1", and 1 1/4", the system can accommodate different drainage needs and flow rates, making it ideal for handling high volumes of liquids. The drain's standard 0.5% slope ensures effective drainage by preventing water accumulation, which is essential for maintaining high sanitary standards in food and beverage facilities.

Furthermore, the drain system is designed to meet the demands of heavy-duty applications. It is rated for Load Class E (DIN EN 1433) and classified as Extra Heavy Duty (ASME 112.6.3), ensuring reliability under high loads. Its customizable lengths and configurations provide flexibility to meet various installation requirements, making it suitable for a range of facility layouts. GDT offers a range of accessories, including cleaning paddle brushes and flush systems, ensuring thorough and efficient cleaning.

The versatility of the 10,000 Series FoodSafe Slot Drain with the Circular Catch Basin makes it suitable for a range of applications across the food and beverage industries. In bakeries, the drain provides hygienic solutions for production floors and washdown areas. In beverage production facilities, it ensures drainage for bottling lines and production areas, preventing microbial growth. Breweries and wineries benefit from a drainage system capable of handling high temperatures and chemical exposure in brewing and fermentation areas. Dairy production facilities can rely on the drain's hygienic design to prevent bacterial growth in milking parlors and processing areas. In meat processing and packaging, the system's construction ensures sanitation while handling heavy loads. The seafood processing industry benefits from its corrosion-resistant properties, ideal for saline environments in processing and packaging areas. Additionally, produce processing facilities can utilize the drain's sanitary design to prevent standing water and contamination in washing and processing areas.

As Global Drain Technologies continues to innovate with products like the Circular Catch Basin, the company remains committed to delivering drainage solutions that meet the unique needs of its customers. With a focus on quality, hygiene, and efficiency, GDT is proud to support industries worldwide.

For more information about the 10,000 Series FoodSafe Slot Drain and the new Circular Catch Basin, visit FoodSafe Drains.