There’s been a wave of industry reports about how control platforms, middleware and business solutions can dramatically improve food and beverage plant efficiencies. Sensor cost, cloud storage, lightweight systems and experienced system integrators are just some of the reasons why enterprises are adding new technologies to plant floors.

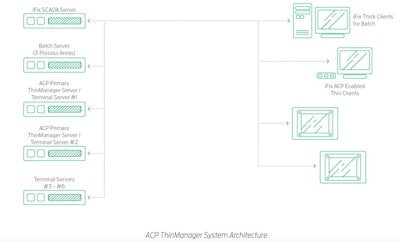

Sometimes it calls for addition by subtraction. Recently, a multinational nutrition company removed the industrial PCs tied to its supervisory control and data acquisition (SCADA) system, replacing them with a thin client. The ACP ThinManager provides the ability to remove software maintenance routines by implementing thin client PCs on the plant floor or control rooms. The processing is done by a central server.

The objective was to reduce PC maintenance costs, speed up disaster recovery and provide redundancy at the client level—all without affecting the validated state of the system, according to Malisko Engineering, the system integrator that implemented the system.

The company operates in food production, so it falls under strict regulations from the U.S. Food and Drug Administration (FDA). Each aspect of its system must be validated through thorough documentation. The FDA validation for this company includes acceptable, trustworthy electronic signatures of processes and batches.

The company’s architecture consists of 10 production areas with individual SCADA servers and 48 thick clients. These thick clients include a mixture of desktop PCs and industrial touchscreen PCs.

“The primary driver for our facility was turnaround time,” says Aric Butowsky, a senior automation engineer at the nutrition company. “We can have a replacement thin client up and running within 10 minutes vs. four hours or more to build a new thick client from scratch.”

The thin client manager allows the use of five monitors from a single thin client; an administrator can view and operate a terminal on the floor, and split any screen into multiple sections with cloud security features. Thin clients don’t store data. By default, USB drivers can’t access these clients, and encryption is part of all communication between clients and servers, including mobile devices.

Malisko set up a proof-of-concept version for the nutritional food producer before installing the thin client system. The system was compatible with its existing SCADA system, which handles production functions and logs production data. However, the company discovered that its batch system couldn’t integrate with the ThinManager system, terminal servers and thin clients.

To address this situation, the integrator used a simulated system off site to verify the company’s SCADA systems and conduct factory acceptance testing (FAT). Within this process, the integrator created installation qualification (IQ) and operational qualification (OQ) protocols for documentation and verification purposes.

With these off-site qualification steps in place, the onsite integration proceeeded in two phases, beginning with a small initial installation of six validated servers and one SCADA system. After the success of the first phase, the company completed the integration with an additional 48 thin clients across the remaining nine SCADA systems.

“The other driver [for the project] is cost efficiency, with the virtualization of the remote desktop services (RDS) server,” Butowsky says. “This allows the elimination of the RDS server hardware and all the industrial PCs in the field.” The benefits also included reduced maintenance procedures—for Windows patches and antivirus updates—from 63 to 21 clients.

The company’s technicians now have the ability to monitor all SCADA systems using a single thin client instead of multiple, configured thick clients. Plus, the new system allows for increased visibility of overall equipment effectiveness (OEE) data on large screens.