We wanted to reduce labor costs and make the work environment less burdensome for operators.”

It’s simple enough, this statement by John Burleson of English Mountain Spring Water in Dandridge, TN. But behind these simple words lies a sophisticated and fascinating robotic installation. It combines roller conveyors, turntables, tight timing, and highly complex end-of-arm tooling in a smooth-running operation that has played a key role in helping this Tennessee water bottler grow.

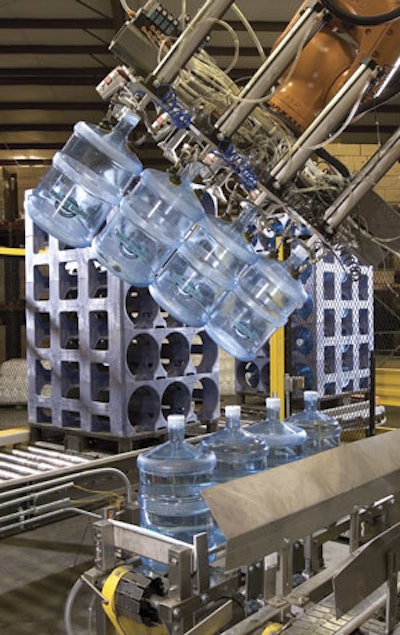

The returnable/refillable containers being handled are 5-gal polycarbonate jugs of water. Empty, a container weighs a mere 2.5 lb, but fill it and it tips the scales at 45 lb.

Until the firm installed its robotic solution, the jugs were handled manually. “We had to rotate people around a lot because loading those full bottles into racks was really tough,” says Burleson.

The solution: a robotic work cell from Aidco with a Kuka robot at its center. Installed early this year, the system

• accepts racks of 30 empty bottles that come from delivery trucks

• turns the racks 180 degrees

• unloads empty bottles from racks and feeds them to a conveyor that leads to rinsing/filling/capping

• loads full bottles back into racks

• turns racks of full bottles 180 degrees

The need for this system really began to emerge some time after the firm installed a rinsing/filling/capping system that’s capable of filling the 5-gal bottles at 20/min.

“To keep this filling system running at that speed,” says Burleson, “we needed two people taking empty bottles from racks and two more putting full bottles back into their racks. Then another two people were involved in forklift operation and two more for overall quality control.”

First robot was for PET bottles

The move to an automated system began to take root in April of 2004. That’s when the firm installed an Aidco KR180 system to automatically palletize cases of PET bottles. The improvement in operations was so impressive, says Burleson, that it got everybody to thinking about automating the unracking and racking of 5-gal bottles, too. Designing and installing such a system was no walk in the park.

“A lot of engineering know-how had to go into it,” says Burleson. “Infeed pressure was an issue where the full bottles are concerned. With five bottles lined up waiting for the end effector to come and get them, that’s 225 pounds of pressure. So Aidco put a spacing gap between bottles. A triggering device with photo eyes and pneumatic arms comes in and separates the bottles. It provides constant spacing so that the end-of-arm tooling comes to the precise location each and every time.”

Packaging actually begins when a fork truck driver removes a rack of 30 empty bottles from a delivery truck. The bottles are arranged 5 high, 3 wide, and 2 deep, and all 30 are oriented with their necks facing the fork truck driver. The driver puts the rack on a turntable. As he backs away, a sensor signals the turntable to turn 180°, so that when the rack is automatically conveyed forward a short distance to the robotic cell, all bottle necks are facing the robot.

The robot sits between two racks and deals with both the leading and trailing racks simultaneously. One stroke removes five empty bottles from the trailing rack, which is being emptied, and places them on the infeed conveyor leading to the filler. The next stroke picks up five full bottles and places them in the leading rack, which is being filled. This is possible because the bottles travel in a closed loop: Freshly filled bottles return from the filler to a position right next to the spot they were placed when the robot removed them from the rack of empties.

Needless to say, building in this kind of functional versatility in the end effector required considerable ingenuity. Picking the 2.5-lb empty bottle from a rack is a fairly simple task performed by three vacuum cups per bottle. These vacuum cups attach themselves to the bottle shoulder to perform their tasks. But keep in mind that the empty bottles are racked two deep. So when the end effector comes back to get the recessed row of five bottles, it uses a pneumatic telescoping device to reach in deep enough to get them.

For full bottles, an entirely mechanical, as opposed to vacuum, picking action is used. A “cradling plate” supports the bottle from the neck finish to the shoulder. An upper jaw closes on the bottle’s shoulder area so that the bottle is firmly clamped between the cradling plate and the upper jaw.

Once the leading rack has all 30 of its slots occupied by filled bottles and the trailing rack is empty, each is automatically conveyed one station forward. That puts the empty rack in a position to be filled. As for the full rack, it moves onto another turntable that rotates it 180°. With this rotation, the bottle necks are once again facing the fork lift driver, who scoops up the rack and carries it to a delivery truck for shipment to customers.

“What used to require seven or eight people now requires three or four,” says Burleson. “And it’s a lot less punishing work. It also occupies a surprisingly small footprint.”

Burleson also notes that the robotic cell handles 3-gal bottles just as efficiently as 5-gal. The racks have a 5-high x 3-across format similar to that used for 5-gal bottles. But where the 5-gal bottles are 2-deep, the 3-gal are 3-deep. And changing over the robotic cell from one size to another?

“It’s all done at the touchscreen control,” says Burleson.