motion control applications.

This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

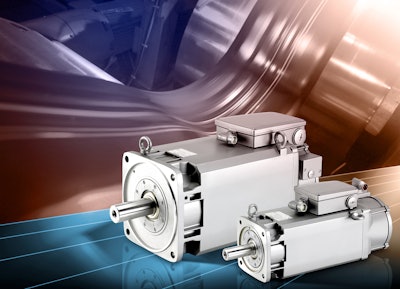

After considerable research and product refinement, as well as extensive field contacts with end-users, Siemens Industry, Inc. introduced the new 1PH8 family of high-performance induction motor drives and servomotors. Available in a wide power range, from 2.8 kW up to 1340 kW, these new motors provide excellent dynamic response, smoother operation and lower vibration levels.

This new line combines induction and high-powered servo technologies to give machine designers and end-users a greater degree of efficiency and more precision in the production process. A single stator and rotor design enables the modular adaptation of the many motor options to provide design flexibility and cost containment.

Designed for the specific performance and environmental requirements of a main spindle on a CNC-equipped machine tool, these new Siemens induction motors have myriad applications in other heavy-duty markets, such as print unit drives on printing presses; rolls and web handling on converting and packaging machinery; crane and hoist elevation; extruders and injection molding machines; metal-forming and welding machinery; assembly line robotic articulation; materials handling gantries and more.

The modular motor platform concept offers designers various options for selecting the optimum unit for an application:

- Assorted bearing designs for increased cantilever forces or increased speeds up to 20,000 rpm

- Shaft designs in a solid or hollow configuration to match the mechanical interface

- Forced-air or water-cooled models for choosing the better method to suit the job

- Induction or synchronous servomotor design for mating the right motor to the size requirements and dynamic response needs; both styles feature the same mechanical and electrical interface to simplify engineering

- Absolute or incremental encoders built-in for high-resolution feedback and enhanced motion control in high power level applications

The 1PH8 motor spindle line is fully compatible with the popular Siemens Sinamics® S120 drives platform to achieve faster commissioning and improved control response. All motors in this new family feature the Drive-Cliq® serial interface and electronic nameplate recognition for plug-n-play start-up.

Earlier families of Siemens motor designs can be upgraded to the new 1PH8 series without difficulty, including the 1PH7, 1PL6, 1PH4, 1PM4, 1PM6 and the upper range of the 1FT6. For more information, visit www.usa.siemens.com/motioncontrol.