VDG (Van der Graaf)

Shelby Township, MI 48315

VDG is the leader in the design and manufacturing of drum motors for belt conveyors in USA & Canada, providing reliable conveyor belt drive solutions for 40 years.

VDG is the world’s leader in the design and manufacturing of drum motors for belt conveyors, with a strong focus on safety, reliability, and longevity. VDG adheres to a simple principle: provide reliable belt drive solutions to the material handling and food processing industries through innovation, continuous research and development, and precision manufacturing. Manufacturing in-house in the USA and Canada since 1985, using cutting-edge production technology and automation, VDG ensures product quality, short lead times, and after-sales service.

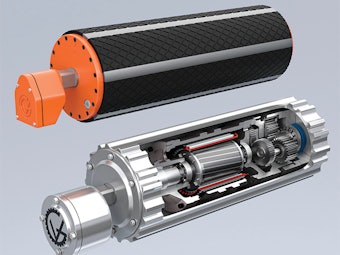

The VDG Drum Motor is a one-component conveyor drive that has all drive components, including the new premium-efficiency electric motor, gear reducer, and bearings, enclosed inside the drive drum, increasing mechanical and electrical efficiency, optimizing space, and promoting operator safety. Designed for 80,000 hours of continuous operation before maintenance, VDG Drum Motors reduce maintenance and operational costs and increase productivity.

All-stainless steel SSV Series Drum Motors, designed specifically for food processing and handling belt conveyor applications, drive modular, wire mesh, and monolithic conveyor belts without using sprockets. The belt profile is either machined directly on the drive drum or on the exchangeable profiled sleeve (XP). The profiled sleeve on the SSV-XP Drum Motor can be easily removed and exchanged for another sleeve to match the belt required on the conveyor. Therefore, the same drum motor can be used when switching to another belt for a different type of processing.

All SSV Series Drum Motors feature an IP69K-rated sealing system, withstand up to 3,000 psi washdown pressure, and eliminate crevices that trap food by-products and bacterial harborage, reducing washdown time and water usage by 50%. Belt profiles are available for all major belt manufacturers.

The IntelliDrive™ Drum Motor features new synchronous permanent magnet motor technology, delivering 40% increased electrical efficiency, a wider range of belt speeds without loss of torque, and an increase in electric motor lifespan compared to a traditional external conveyor drive. It enables onsite diagnostics, full motor indexing speed control, and communications with other automated plant equipment.