TNA Solutions

Coppell, TX 75019-3800

TNA is a global complete solutions provider in food processing & packaging. Dedicated to helping customers achieve ambitious goals with performance, responsibility and a personalized approach, TNA delivers the highest levels of safety & community impact.

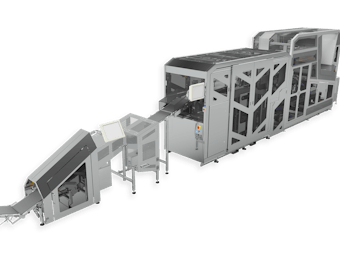

Specialist provider of complete food line solutions, TNA offers a wide range of cutting-edge technologies to meet the diverse needs of the food industry. The company’s flagship product, the tna robag®, has been one of its best-selling high-speed vertical, form fill and seal (VFFS) packaging machines for over four decades, renowned for its reliability and performance. The tna ropac® 5 is the world’s fastest case-packing system for flexible bags, capable of packing up to 200 bags per minute. Designed with TNA's patented semi-rotary bag stacking technology, the system specifically caters to the packaging needs of small-to-medium, pillow-style snack bags. Its tool-less changeovers and compact design are highly valued by manufacturers, as it allows for seamless integration into production lines and ensures optimal performance in packaging operations.

TNA’s training solutions combine classroom-based learning with practical problem-solving and interactive participation for a training experience that goes far beyond standard operating instructions. Our team of technical experts offer a variety of convenient ways to learn, including online, offsite and onsite. We have many years of experience in packaging and processing in almost every type of product application. We can even offer in-depth training sessions to staff wherever they are in the world, using Microsoft HoloLens technology to allow trainees to practice operations on virtual equipment remotely before moving onto expensive real-world systems.

The tna intelli-assistTM platform is a pioneering solution that leverages the power of extended reality (XR) to create a fully functioning and interactive digital twin of any planned or current operations. It enables food manufacturers to virtually create and integrate equipment and technology into both new and existing production lines. Delivering 95% planning accuracy and reducing reworks down to zero, the solution leverages a digital twin environment using spatial technology. These immersive replicas of manufacturing sites allow food producers to visualise plant layout, detect and prevent clashes, virtually replace systems, and validate plant design and installations—all within a low-risk, simulated environment.The platform brings together multiple stakeholders across various locations into one collaborative space, streamlining teamwork and saving our customers time, effort and money. Guided by TIA™, the platform's virtual assistant and mascot, food manufacturers benefit from simplified onboarding, ensuring seamless navigation and enhanced efficiency.

TNA is a global leader in food processing and packaging, dedicated to helping customers succeed in a changing world. With a track record of over 40 years, TNA has successfully installed more than 16,000 systems in over 130 countries. The company’s focus goes beyond delivering products; TNA provides comprehensive solutions designed for the highest output, minimal downtime and reduced total cost of ownership. TNA’s extensive offer covers every aspect of food processing and packaging, including handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting, labelling, metal detection, verification and end of line solutions. Through a consultative and customer-centric approach, the company’s experts ensure that goals are not only met but exceeded. TNA’s advanced product line controls, integration capabilities and SCADA reporting enable optimal performance and operational excellence.

In addition to TNA’s broad portfolio of processing solutions, the company’s packaging technology advancements, such as the ‘Perfect Pair’, add significant value to complete integrated lines. This powerful combination features the tna robag® 3e, the latest iteration of the renowned packaging system, along with the tna auto-splice 3. Together, they enhance production uptime, simplify servicing, improve diagnostics and reduce waste. Add to this secondary packaging solutions such as the tna ropac® 5 - the world’s fastest case-packing system for flexible bags – and manufacturers have all of the tools they need to optimize resource usage and achieve operational efficiencies, contributing to efficient and sustainable operations.

Mukul Shukla