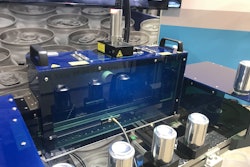

Created specifically for distilleries, Proof Perfect filling systems are made with 316L stainless steel and feature a dry-floor design, which includes a fully-enclosed, sloped-deck base. From single-valve fillers and single-head cappers to 48-valve rotary machines, Proof Perfect solutions can be configured to meet the needs of small, artisan distillers to the highest volume distilleries in the most demanding production environments.

This new family of solutions includes best-in-class filling and capping technologies from Federal and Zalkin, with a variety of standalone fillers as well as filler-capper monoblocs and rinser-filler-capper tri-blocs. Proof Perfect systems maximize operating efficiencies, improve clean-in-place processes, and simplify product changeovers.

“Distilleries want fillers that are more sanitary and can be effectively cleaned more quickly during product changeovers. The growing popularity of flavored spirits is driving this demand, because distilleries have a larger number of different products and shorter production runs,” said Paul Kearney, Vice President of Sales at ProMach Filling Systems. “ProMach is well-established in the distilled spirits industry with our cappers and labelers, and Federal has thousands of fillers installed in a wide variety of beverage sectors. Now, we’ve leveraged our experience in the dairy and juice industries and applied those high sanitary standards to enhance our fillers for distilled spirits.”

Proof Perfect fillers from Federal feature fully-sealed filling bowls and gravity filling with light pressure and light vacuum capability. All systems are designed to meet Class 1, Division 1 Explosion Proof requirements. Field-proven filling valves feature an engineered plastic centering cone that gently handles glass or PET bottles and provides proper handling of crooked-neck bottles. With no o-rings in the valve nozzle tips, these fillers eliminate the risk of o-ring debris falling into bottles. Proof Perfect filling nozzles are hygienic and easy to clean. Product and container changeovers are achieved with no tools required.

Featuring automated CIP (clean-in-place) systems, Proof Perfect fillers are capable of various processes from simple purge-and-chase cycles to multi-cycle purge-rinse-clean-and-rinse processes required for flavored products and cordials. The fillers are compatible with product, rinse and CIP chemical collection and processing systems.

Rotary fillers can include 10, 24, 30, or 48 valves to achieve speeds up to 450 cpm while inline fillers can include 1, 4, 8, or 12 valves to achieve speeds up to 75 cpm. Capping turrets and cap handing technologies from Zalkin are available for plastic screw-on closures, roll-on pilfer proof (ROPP) aluminum closures and push-in and snap-on closures, including t-corks and bar corks. All Proof Perfect fillers and cappers are available as either stand-alone systems or integrated bloc solutions.

Proof Perfect filler-capper monoblocs incorporate a Federal rotary filler and a Zalkin rotary capper. Proof Perfect rinser-filler-capper tri-blocs add and integrate a Federal rotary rinser. Integrating multiple operations into a unified, high-performance monobloc or tri-bloc maximizes operating efficiencies and saves floorspace.