FPS Food Process Solutions Corp.

Richmond, British Columbia V6V 3B9

FPS Food Process Solutions is a global leader in turn-key food processing solutions. We provide innovative systems to ensure the highest efficiencies and to meet the most stringent sanitary demands at the lowest total cost of ownership.

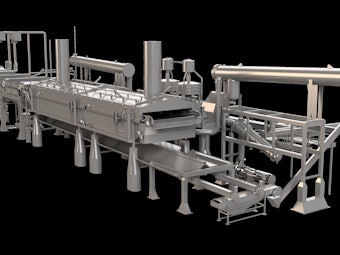

Product SectorsFreezers and ChillersFPS offers a range of innovative freezing and chilling technologies for maximizing performance and ensuring the highest hygienic standards. They include Spiral Freezers and Chillers, IQF Tunnels, Impingement Freezers, French Fry Tunnels, Carton Freezers - (CF) MultiPass and (VRM) Variable Retention MultiPass - and the Spiral Immersion System (SIS)™.Spiral Freezers and chillersFPS spiral freezers, chillers, and coolers are custom designed to meet your specific requirements. Aiming to build long-term partnerships with customers, we listen to each of your unique needs and concerns and incorporate these into our designs. Our focus on details ensures the spirals are optimized for all applications, from raw to ready-to-eat foods. We offer a range of innovative technologies to maximize performance and ensure the highest hygienic standards, all integral to lowering total cost of ownership.Spiral Immersion System (SIS)™ FPS Spiral Immersion System (SIS)™ is a revolutionary new patented food processing platform for chilling, freezing, pasteurizing, and sous vide cooking packaged food products. This energy-saving immersion system consists of twin spiral conveyors in a tank of liquid, usually water or brine. It is faster and cheaper for producing a safer food product with better quality and longer shelf life, all while taking up less space than traditional air chilling.IQF TunnelsFPS’s range of Individual Quick Freeze (IQF) tunnel freezers implement a combination of air and mechanical fluidization techniques to ensure products like fruits and vegetables are efficiently and individually quick frozen with high quality. Our Air Flow IQF technology ensures gentle handling by continuously lifting and separating products as they move through the tunnel. The combination of our IQF technologies with our hygienic design fundamentals results in a high-performance tunnel freezer satisfying the most stringent food safety requirements.Impingement FreezersFPS impingement tunnels have been developed for a range of cooling and freezing requirements, including pre-cooling and crust freezing for further processing as well as complete freezing. Our impingement tunnel incorporates a hygienic pressure duct system to deliver high velocity air that quickly cools or freezes products. The proprietary air duct design ensures efficiency and maximizes yield, even with products of varying geometries. The impingement freezers are available with multiple belt pass and lane arrangements and varying belt widths and belt types to match your production needs.Carton FreezersFPS carton freezing solutions include two options, Carton Continuous Flow (CF) freezers and Variable Retention MultiPass (VRM) freezers, to fulfill a range of cooling, chilling, and freezing requirements with single and variable retention times. Utilizing MultiPass Air Flow Technology, our carton freezers provide true counter-flow heat transfer. This ensures each carton exits at the same temperature irrespective of its shelf position. The resulting freezing consistency and energy efficiency translate to energy savings, carbon footprint reductions, and consistently optimal product quality.Fryer SystemsSubsidiary GEM Equipment of Oregon, Inc. has been a manufacturer of custom food processing equipment since 1968. Today, GEM designs, builds, and installs single and two-stage fryers based on small to large throughput capacities – there are no two alike. Demonstrating engineering ingenuity with safety and maintenance in mind, GEM fryers are internationally recognized for their distinct features and unrivaled performance. GEM offers full service, from procurement to setup, custom designing fryers as stand-alone machines or complete processing systems to meet your specific needs and plant layouts.Blancher SystemsGEM Hump Belt Blanchers are designed to ensure gentle product handling, consistent heat distribution, and uniform blanching performance. The unique hump belt panels are made of perforated stainless steel and manufactured by GEM inhouse. GEM Rotary Blanchers process food products using a heat transfer medium that can be comprised of liquid, such as water, or gas, vapor, or a combination thereof. Consisting of an elongated, cylindrical perforated drum in a tank filled with heated water, the basic rotary blancher enables higher efficiency, processing more pounds of products per hour while taking up a smaller footprint.Pulsed Electric Field (PEF) TechnologyThrough our collaboration with technology partner OptiCept Technologies, we've combined cutting edge PEF technology with decades of experience in hygienic food processing equipment design. The next generation FPS PEF system is the most efficient and hygienic collaboration for processing solid foods in the market, all while minimizing total cost of ownership. FPS PEF system brings distinct advantages to this sector. Distinct advantages to food manufacturers include enhanced raw material extraction, less energy and water usage, less drying and freezing time, and improved product texture and quality.

GLOBAL PARTS & SERVICE CENTERS Experience tells you the importance of efficient and responsive service - FPS has you covered. Our 24-hour support hotline puts you in direct contact with a real-world technician, not just an answering service. With the largest freezer service team and spare parts inventory in the industry, FPS support can assist in getting your equipment back in production with minimal disruption. RETROFIT SERVICESOur retrofit specialists are not only experts with our equipment, but also equipment from other suppliers. We offer comprehensive retrofit packages from systems evaluations to complete structure and enclosure rebuilds. With recent global attention to environmentally friendly practices and food safety concerns, your existing equipment can be evaluated and upgraded to energy efficient operation and meet current hygienic demands.24/7 SERVICE HOTLINESCanada:+1 604-330-1262HK/ China:+852 5803-3114Brazil:+55 11-4380-1935Australasia:+64 9-801-5762United States:+1 989-704-7953Europe:+31 85-208-3768Thailand:+66 2-430-4191[email protected]

FPS Food Process Solutions is a global leader in turn-key food processing solutions. We provide innovative systems to ensure the highest efficiencies and to meet the most stringent sanitary demands. These factors transform into superior food quality, lowered total cost of ownership, and maximized profits.

Established in 2010, FPS has a combined 800,000 sq. ft (74,500 sq. meters) of space in 20 locations including its Canadian headquarters, manufacturing, and warehouse facilities as well as international sales offices across six continents. Joining the global FPS family are Charlottetown Metal Products (CMP), Total Solutions Ltd (TSL) and GEM Equipment of Oregon (GEM) as subsidiaries and OptiCept Technologies as a strategic partner in PEF technology, further diversifying the company’s product offering with a “one stop shop” to meet customers’ needs.

We solve food processing’s toughest challenges. By providing best-in-class turn-key food freezing and chilling equipment and complementary end-to-end solutions, we ensure our customers’ products are managed through every step of the production process. Designed to seamlessly integrate and create full processing lines, from raw receiving to packaging, FPS are with you every step of the way.