There’s rarely a shortage of ideas about how to boost industrial growth and innovation. Most such discussions, however, typically spring from a personal, anecdotal, or industry vertical experience point of view. To get a broader perspective and determine the most beneficial areas of focus for specific, quantifiable improvement, the National Institute of Standards and Technology (NIST)analyzed data collected through extensive interviews and surveys with researchers, developers, manufacturers and other stakeholders.

Their analysis resulted in four studies that identify the critical technical barriers to the adoption of specific manufacturing technologies. The studies also estimate the positive economic impacts of eliminating those obstacles—which the NIST says would total more than $100 billion in annual savings.

It’s not surprising that three of these four studies focus on technologies covered regularly by Automation World due to their relevance across the discrete, process and batch manufacturing industries. These three technology areas are: additive manufacturing, advanced robotics and automation, and smart manufacturing. The fourth area addressed by the NIST study focuses on roll-to-roll manufacturing—the fabrication of electronic devices on a roll of flexible plastic or metal.

The largest predicted cost savings across the studies are tied to smart manufacturing (defined by NIST as processes in which all manufacturing data from design to finished product is electronically exchanged and processed) and advanced robotics and automation. NIST suggests that smart manufacturing could reap $57.4 billion in annual saving to industry and advanced robotics and automation could save another $40.1 billion.

Despite its relatively recent entry into the manufacturing space, additive manufacturing/3D printing could save industry another $4 billion annually, according to NIST.

Across all these areas of focus, NIST’s analysis determined that U.S. industry must address currently unmet needs for measurement science and proof-of-concept demonstrations for emerging technologies. “Gaps in the technology infrastructure—including the lack of reliable measurement and test methods, scientifically based standards, and other formal knowledge and tools—limit advanced manufacturing’s further development and adoption,” says NIST economist Gary Anderson, coordinator of the studies.

Because the studies only considered the benefits directly attributable to closing the identified technical gaps in each sector, NIST says the impacts noted in the research estimates are conservative. “If we consider the larger-scale outcomes brought about by meeting these needs—such as new and improved products, increased production quality, long-term industry growth and job creation—the impacts would be significantly higher,” Anderson says.

NIST researchers also note that increasing access by small- and medium-sized manufacturers to the same state-of-the-art methods, tools and knowledge as their larger counterparts is a need that must be met to realize the projected benefits of the research.

In general, the studies highlight key strategies for overcoming technical barriers and fortifying advanced manufacturing, including:

- keeping standards and performance measures nonproprietary

- using public research institutions to develop those tools

- working through manufacturing research consortia and technology extension services to ensure that all manufacturers—especially the small- and medium-sized enterprises mentioned above—can access them

Looking more specifically into the research areas most relevant to Automation World readers across industry, NIST identified the following needs:

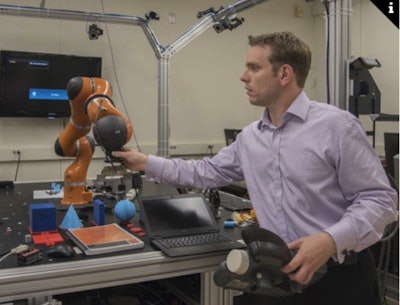

Robotics

Safe human-robot interaction. Universal standards are needed for developers of robotics technologies and the application of these technologies in manufacturing settings with robots working in close proximity to people.

Sensing and perception for unstructured (or less-structured) environments. Improved perception (and the ability to plan and re-plan the robot’s actions based on what it “sees” and “knows”) gives a robot greater autonomy, lessening its demand that its work environment meet stringent tolerances.

Objective, low-cost performance characterization. Make it easier for robotics users to know what they are buying and for developers and suppliers to show what their systems do.

Interoperability and modularity. Plug-and-play for system components, enabled by standards for physical and electronic interfaces and software interfaces or translators.

Intuitive interfaces. Enabling rapid programming and training without specialized skills. There have been notable advances being made in this area by collaborative robotics suppliers.

Modeling and simulation. NIST advocates for wider application of virtual factory floors that use modeling and simulation calibrated based on real-time data feed from robots, machine tools, sensors and control systems on the floor.

Smart manufacturing

Managing digital data streams through models. This involves use of CAD models including material characteristics, simulation models of part creation and plant layout, and rapid automated costing functions.

Enhanced sensing and monitoring. NIST says this includes “state estimation” of critical manufacturing machines (e.g., vibration, acoustics, temperature, tolerances and pressure) and real-time monitoring of product attributes as they move through various stages of the production process.

Seamless transmission of digital information. Included here are wireless transmission of digital information without interference from other data channels, seamless integration of smart sensors, interoperability between different platforms such as CAD/CAM, and secure data transmission (wired and wireless).

Advances in analyzing data and trends. NIST says this includes interpretation and aggregation of data from sensing and monitoring networks, use of Big Data techniques for manufacturing, predictive maintenance, reduction of false positives, and cloud computing and fee-for-service cloud-based algorithms for product design, simulation and manufacturing design.

Efficiently communicating information to decision makers. Technologies involved here include comprehensive information interfaces, human-computer interaction-based design, and easy-to-interpret interfaces accessible from any location.

Determining required action and implementing action. Taking industrial communication to the next level involves incorporation of real-time feedback from enhanced sensing and monitoring data into automated optimization-based decision making that functions independent of human interaction, machine learning decision-making algorithms, and reconfigurability of manufacturing systems.

Additive manufacturing

One of the biggest issues related to additive manufacturing (AM)—identified by NIST’s research—revolves around end users’ current inability to verify AM part quality and performance or identify whether the potential issues with AM part performance and reliability are caused by underlying issues with AM processes, AM equipment, or the materials used.

NIST says its research provides evidence that “proprietary standards [in the AM field, in particular] create market distortions by conveying market power through branding and reputation.” This means that “gaps in [voluntary consensus] standards may tend to favor the interests of AM systems manufacturers.” The result of these factors are, according to NIST, causing AM research, development and deployment to become excessively costly and are weakening private investment incentives.

As a result, standards-related issues top the list of NIST recommendations to address in the AM arena:

Standards. As noted above, standards are needed to improve confidence via reproducibility across and reference data for materials and manufacturing methods and AM processes.

Metrology. Specifically, real-time, in situ metrology—enabled by integrated sensors—should be used for real-time feedback during a build.

Design Allowables. NIST explains that this recommendation relates to design optimization tools and protocols for complex builds.

Modeling and Simulation. This pertains to the use of high-fidelity process modeling and simulation for different materials and designs.

Surface Finishing. NIST recommends the use of cost-effective approaches to improve surface finishing of metal AM parts and standards for measuring surface finish and tolerances.

Testing Procedures. NIST supports the development of innovative mechanical testing procedures for AM.