When it comes to effectively managing a batch recipe, there’s no such thing as having too many cooks in the industrial kitchen.

Whether it is a food and beverage, pharmaceutical or chemical company, each department within the organization needs to understand the dynamics of every recipe in order to meet specific needs. From finance (understanding costs) to purchasing (managing materials) to quality control (meeting specifications) to maintenance (taking care of equipment), and, of course, production (making the product), everyone must have access to the basics of the batch.

To that end, batch management is a critical application for managing orders and the execution of recipes across plant floor equipment when variations in the material usage and settings change between products. And full-blown batch management products, like Schneider Electric’s Wonderware’s InBatch software, are designed to manage flexible batching processes—from recipe modeling to simulation to batch scheduling and reliable execution with sophisticated equipment and material management..

Tied directly into the control architecture to interact with the process, batch management systems are effective for multi stream and multi product plants. It can be overkill, however, in a single stream production environment or when formula management is all an organization needs.

“Many production processes do not require large flexibility, particularly when it comes to packaging,” said Michael Schwarz, MOM & EMI marketing manager for Wonderware Software global solutions. “Food and beverage and life sciences customers want recipe management systems to safeguard consistent quality and reduce cost of regulatory compliance without the overhead of sophisticated batch management.”

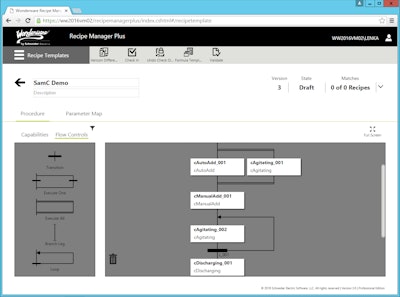

To accommodate single batch and production line processes, Schneider Electric developed Wonderware Recipe Manager Plus, which simplifies the recipe deployment and execution within manufacturing operations.

Recipe Manager Plus is control system-neutral software designed specifically for formula management and download. It is scalable in adding procedural execution management functionality, using state interface functionality in line with the ISA 88.01 standard on batch control.

Integration with OPC UA and Wonderware System Platform enables formula and procedure parameters to be downloaded to almost any automation system. The product includes a role-based Web interface that can be shared across the work team, embedded within an existing HMI or in browsers on panels, workstations or any mobile device that is HTML5 compatible. And, security is maintained with SSL encryption via Wonderware ArchestrA Security Token Service.

Recipe for Life Science

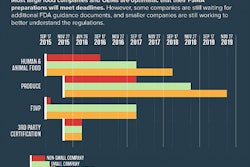

Recipe Manager Plus version 3.5, unveiled this week at Wonderware LIVE, adds functionality to support life science regulatory guidelines, as well as enhancements for importing a “golden batch” formula from execution history.

New “done by/check by” electronic signature settings allows for documentation of every user action. Electronic signatures, audit trails and reports are included to help companies comply with U.S. Food and Drug Administration (FDA) regulations and good manufacturing practices (GMP).

Separately, the “golden batch” set up—which is an industry term used to describe a recipe that provides the best quality under the most effective conditions—can be now turned into a new formula version or new formula template for future use. Automatic electronic records of recipe versions and execution details help to fine tune recipes and lead quickly to the golden batch, which then can be enforced to maximize production output.

“There is need for more documentation and governance due to regulations, but there is also a need for more agility to take product variations to the market for a competitive advantage,” Schwarz said. “We believe having a focused approach to recipe management, with no specific PLC orientation, is unique in the market.”

And back to all those cooks in the industrial kitchen, a key aspect of Recipe Manager Plus is its web-based user interface, which can be leveraged across a company network. It can be accessed by individuals in the enterprise, in R&D, in central engineering and in the local plant, and includes built-in governance functionality configurable to each individual’s role in the organization. That’s a recipe for success.