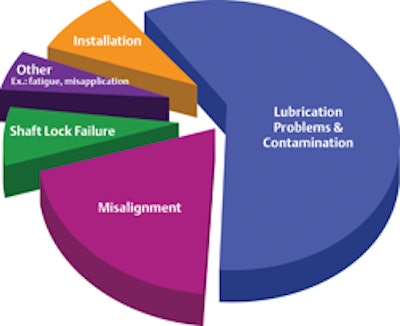

The wheels of industrial automation turn on bearings, so why do those wheels often vibrate, clatter, squeak, drag and overheat? Bearings can fail for lots of reasons. Most failures (as shown in Figure 1) are related to lubrication and contamination, but myths and misconceptions handed from one generation of maintenance engineers to the next help perpetuate many easily avoidable problems. These myths fall into three general areas of bearing use: installation, misapplication and lubrication.

Installation myth #1: It's okay to hammer a bearing into position if needed - FALSE.

Never strike a direct blow to bearing. The rolling elements and raceway are hardened, but can still be damaged. A hammer blow can leave dents in the raceway that can cause noise and dramatically reduce bearing life. If installation is difficult, first check the shaft diameter, look for burrs, dirt or corrosion on the shaft. If needed, use a press to slide the bearing on. Apply pressure equally on the face of the inner ring to avoid damaging the raceways and rolling elements.

Installation myth #2: Off-the-shelf TGP shafting is the best option - FALSE.

It's much more important to know the shaft's tolerance range to be sure it meets your bearing manufacturer's spec for diameter and roundness. Review the bearing manufacturer's recommendations and measure/specify the correct shaft diameter.

Installation myth #3: It's fine to hand-tighten setscrews one at a time - FALSE. Setscrews should be tightened to the manufacturer's recommend torque. Under tightening can allow the bearing to slip on the shaft. Over tightening can distort the raceway or crack the inner ring. Use the "half-full/full" rule for tightening setscrews - tighten the first setscrew to half the recommended torque, the second setscrew to the full torque, then go back to the first setscrew and apply full torque.

Application myth #1: Bearings should not be hot to the touch - FALSE.

Normal bearing operating temperatures can range from 80°F to 150°F, but certain applications may run higher or lower. Most bearings are rated for -20 to 220°F, but can be supplied with special grease, seals or heat stabilizing processes that allow them to operate at higher temperatures. Bearings normally run hotter at start up or right after re-lubrication because excess grease increases drag and friction in the bearing. Spikes up to 50°F are normal at start-up, and 30°F after re-lubrication. As the rolling elements purge excess grease through the seals, the bearings return to steady-state temperatures.

Application myth #2: Bigger bearings are always better - FALSE.

Bigger bearings with a higher load capacity may show a higher fatigue life, but if the load does not achieve the minimum requirement, the rolling elements can skid along the raceway instead of rolling. This can cause high temperatures, excessive wear, lubrication breakdown and bearing failure.

Application myth #3: Sealed/lubed-for-life bearings will last forever - FALSE.

Bearing life depends on grease life, which is affected by the operating conditions (speed and load) and environment (temperature and contamination). Grease life can be improved with enhanced seals, proper installation and proper grease selection. Ultimately, the best bearing is the properly lubricated bearing.

Lubrication myth #1: Re-lubrication once a year is sufficient - FALSE.

Start by reviewing the bearing manufacturer's lubrication recommendations. These will give amounts and intervals as suggested starting points, but actual lubrication intervals may vary quite a bit, depending on load, speed, temperature, or environmental conditions. Applications with higher speeds, temperatures, or heavy contamination sometimes require frequent re-lubrication, possibly weekly or daily. By contrast, a mounted ball bearing in a lightly loaded, low-speed, clean environment may do fine with re-lubrication at 12 to 24 month intervals. Certain applications may need to be monitored and lubrication intervals/amounts adjusted accordingly.

Re-lubrication replenishes grease when the current grease breaks down or deteriorates because the base oil breaks down due to temperature. Without this, the lubricating property is gone and the result is metal-to-metal contact. Re-lubricating the bearing replenishes the oil, maintaining the proper film.

Pumping new grease into a bearing also helps flush away contamination. Many mounted bearings are designed to allow grease to enter the bearing cavity as close to the rolling elements as possible. As more grease is added, the old grease is pushed out of the seals (if the seals are purgeable). The purged grease carries out contaminants and keeps dirt away from the seals.

Lubrication myth #2: Always add grease until it purges from the seal - FALSE.

If you pump grease into the bearing until it purges out the seal, you probably have completely filled the bearing cavity. Excess grease can increase operating temperature and may create enough pressure to blow the seal out. However, in low-speed or dirty conditions where contamination may easily enter the seals, filling a bearing with grease may help improve performance. Application experience will dictate when the entire bearing cavity should be filled.

Lubrication myth #3: If a bearing makes noise, grease should be added - FALSE.

If a bearing is making noise, internal damage has likely occurred. This increases over time, with the potential for catastrophic failure. Adding grease may provide temporary relief, but a noisy bearing should be closely monitored and replaced at the first opportunity. The root of the failure should also be investigated either with independent or manufacturer failure analysis (manufacturer analysis requires removal of the bearing as soon as possible to aid in a more accurate diagnosis of the problem).

Lubrication myth #4: Any grease will do - FALSE.

Greases DO differ. Some may be incompatible because of the different thickeners (soaps) used. When two incompatible greases are mixed, they may thicken and harden or become thin and leak out of the bearing. For example, many electric motors use a polyurea thickener while some mounted ball bearings use lithium-complex thickeners. These greases are borderline compatible, and depending on the actual make up, may not work together. Grease types can also be incompatible based on the viscosity or type of oil in the grease, so consulting a lubrication supplier is always recommended.

Lubrication myth #5: Just shoot grease through the fitting - FALSE.

Always clean grease fittings and the grease gun tip. It's good practice to put the grease gun tip in an oil bath or wrap it with a plastic cover to protect it.

Your plant's uptime and OEE may "turn" on your bearings' good health. If you are not achieving the desired operational life for some of them, a bearing manufacturer can assist you with proper selection and troubleshooting.

Ian A. Rubin is Director of Marketing, mounted bearings, for Sealmaster, System Plast and Browning-branded products at Emerson Power Transmission Solutions.