Earlier this year, MGS Machine, via its European partnership with INEL, introduced a line of pharmaceutical line-level serialization and aggregation equipment to the U.S. market designed to enable product manufacturers and contract packagers to comply with fast-approaching regulatory requirements pertaining to track-and-trace initiatives.

The MGS line includes carton inspection machines, aggregation units and software. All carton inspection units incorporate either inkjet or laser printing, as well as vision systems. Some units can be equipped with tamper-evident labeling and/or checkweighing equipment.

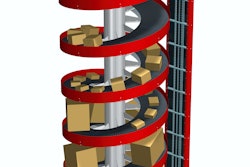

Customers requiring equipment that can function within a small footprint continue to influence MGS machinery development and design. MGS President and CEO Richard A. Bahr says, “One of the hallmarks for MGS is getting a lot done in a little space, especially in the lifescience market where space is at a premium.”

Controls and automation systems play a role in MGS’s space-economical approach. Bahr explains, “Our HMI is the single point of contact for both machine control and for the serialization software. There’s no need for two or three monitors, which can be confusing, waste time and take up unneeded space. We have all functions consolidated into our touchscreen, including recipe setup for new products requiring print, vision, labeling, checkweighing, or all of the above.”

He says by using PC-based HMIs, MGS machinery can connect to other OEM equipment on the packaging line, such as printers and cameras. That permits control of all functions from a single touchscreen. “Many printer and vision camera manufacturers now provide OEM interfaces so that the control panel for their hardware can be emulated on a PC,” he says. “As such, now that PCs are readily available as HMIs, we bring the two together seamlessly.”

For the U.S. market, MGS standardized on Rockwell components for both the PLC and the HMI. A PC-based HMI is employed for the interface. “We have been very satisfied with the Rockwell components and our service from their company,” says Bahr.

While the pharmaceutical line-level serialization equipment is new in the U.S., the machinery has been employed for years in Europe. (MGS cannot disclose the names of the global companies using their serialization equipment).

“Because they were first introduced in Europe, we have both Siemens and Rockwell controls platforms designed for all models,” says Bahr. “In Europe, we primarily use Siemens for the PLC and Beckhoff for the HMI as that [brand] is more user-accepted in that marketplace.

“MGS tries to tailor its offerings with sensitivity to the marketplace or regional preferences,” says Bahr. “Oftentimes, prospective customers will [indicate] their preferred platform in their specifications. We do lead with Rockwell and Siemens as our two primary platforms as that covers most of what we need for the global market.”

MGS’s PV-600 carton inspection machine was unveiled in the U.S. at last March’s PACK EXPO East event. Bahr says the company’s manual aggregation unit (MAS Top) offers fully automated aggregation with the MGS MatriX case packer, which is also designed for serialization applications.

“The ‘PV’ machines provide automatic handling of cartons and perform both print and vision inspection on the carton,” he notes. “Depending on the model, the PV units will print thermal inkjet or laser codes and use vision systems for verification. We can also label and/or checkweigh the carton. The smallest unit is 0.500 meters, not using up any more space than an existing small discharge conveyor would at the end of the cartoner.”

Although this particular serialization/aggregation equipment line is designed primarily for the pharmaceutical industry, Bahr notes, “Customers in other markets are interested in print and inspection, particularly in brand protection strategies, so we have the capability of deploying [the equipment] into food, cosmetic, personal care, electronic, or other applications.”