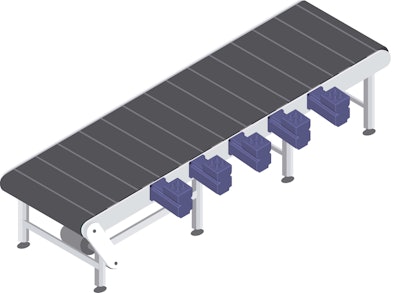

Applied Motion Products customized an integrated stepper motor package that offered a single motion control solution for an innovative conveyor system by Intralox that it says saved on space, wiring, and cost over conventional motor and drive solutions.

Capable of handling packages in a variety of configurations, the system needed a motor and actuator assembly that could position as rapidly as the analog control system updating target position every 4 msec. In addition, the motor needed to have the flexibility to address changing requirements for alignment, sorting, and singulation for different industry applications such as food processing, beverage handling, baking and industries.

Applied Motion designed the STM/SWM integrated stepper motor package with the efficient and flexible positioning required by the conveyor system. Combining a motor, drive and control in one package, the STM/SWM incorporates an encoder with capabilities for automatic stall detection and prevention. The built-in encoder provides feedback to the integrated controller on the motor’s actual position and closes the feedback loop to avoid limitations associated with stepper systems.

Q Programmer™motion control software incorporated into the STM/SWM integrated stepper motor package enables easy configuration of motor operation to match requirements of different conveyor applications. On-board EtherNet/IP communications of the integrated stepper motors replace noisy analog control signals with a digital signal, eliminating the need to run long signal wires from as many as 100 motors to a central PLC and allowing the conveying equipment to perform at high speeds with high precision not affected by noise.

Remote service system for aseptic package systems

As part of its expanding Digital Service portfolio, aseptic packaging system builder SIG recently launched Remote Services, helping food and beverage manufacturers service their filling machines and generating more filling line uptime.

Remote Services is a new digital service that can instantly connect a customer or service engineer to a SIG service expert from anywhere in the world. By using video-enabled smart glasses, SIG can provide a secure live feed to a SIG expert who can guide users through solving any fault or issue.

SIG developed Remote Services in response to new customer challenges and demands. With the food and beverage industry facing higher competitive pressures, operational complexity, and shorter production cycles, manufacturers can no longer afford long waiting times for support and the risk of downtime.

Remote Services ensures SIG’s customers receive fast response times, an improved first-time fix rate, more data insights and analysis, and ultimately more filling line uptime. In addition, Remote Services can help reduce costly travel times, expenses, and CO2 emissions.

“Many companies develop digital solutions just to have them in their portfolio,” said Dr. Christian Grefrath, SIG’s Global Service Product Manager and Project Lead for Remote Services. “But we listened to our customers and matched their needs with new possibilities arising from digitalization. Now we have a new solution that fosters our customers’ success by bringing our expertise much faster to the place where it’s needed. We will continuously build up our Digital Service portfolio while always having our customers’ demands in mind.”

Remote Services is part of SIG’s value-adding Smart Factory platform – a commitment to delivering smarter filling line solutions and technical services that help transform customer filling plants into intelligent and connected factories.

As part of the Remote Services solution, SIG smart glasses provide a live feed from the customer plant to a SIG Remote Services expert. This remote service creates a secure data connection and enables the SIG expert to see exactly what the onsite customer or service engineer sees. The Remote Services expert can then send detailed instructions or technical drawings to guide them through resolving the issue. At the same time, the Remote Services expert can identify any parts that need replacing and order them for fast delivery and repair.

“We tested Remote Services together with one of our customers and could instantly help them more quickly and effectively when they had a technical issue,” adds Ferdinand Schneller, Head of Technical Service for SIG in North America.