This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

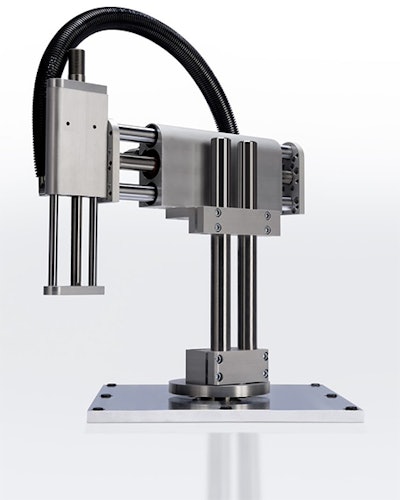

LinMot USA’s DM linear module pick-and-place unit boasts 30% faster speeds than its competition. The unit will be displayed with rotary turning capabilities. This purpose-specific robot is ideal for industrial parts handling applications, all the way to food and pharmaceutical packaging, processing, automation, assembly, and material handling.

Designed for applications with strict sanitary requirements, the hygienic SM pick-and-place is constructed with stainless steel that holds up to harsh chemical washdown. This dedicated robot offers either IP69 or IP67S-rated protection, is laser welded and fully enclosed. It easily integrates into various packaging systems for food, baking, confectionary and personal care applications. This fully electric solution achieves over 95% energy savings and reduces carbon dioxide emissions by nearly 97%.

The LinMot PR02 is ideal for a variety of applications, such as aligning baby wipes, capping bottles, product placement and more. To provide a full solution, it is combined with a rigidly supported EM Module to provide the horizontal axis of travel. Featuring an external sensor, operators can choose between incremental or absolute to provide a high-resolution torque measurement system.

Other demonstrations will include an Edgewater heavy-duty pick-and-place, which is ideal for industrial applications, as well as a new delta robot demonstration in conjunction with the University of Laval, and much more.