The Defender Boasts a Variety of Upgrades to Protect Workers from Robotic Processes.

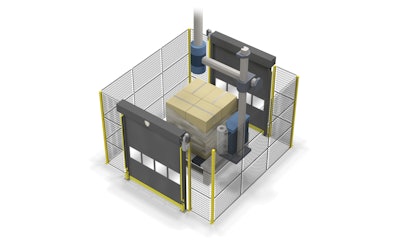

Rite-Hite Machine Guarding, a manufacturer of industrial materials—such as industrial doors, dock equipment, and safety barriers—has updated its industry leading automated barrier door, the Defender, to protect employees from automated stretch-wrap machines as well as other robotic machine movement zones. The product will now feature upgrades to its non-contact safety switch configuration, control systems, and interlocking capabilities.

The Defender’s automated door is designed to be high-speed and high-cycle, to safely separate machine operators and manufacturing processes. The company explains that as more and more suppliers incorporate robots into wrapping processes, it becomes increasingly important to protect employees and pedestrians from coming into contact with the moving—and potentially dangerous—parts of those machines. With these suppliers adding other automatic functions to their floors (intelligent conveyors, AGVs, and AS/RS systems), the safety methodology should be similar to that of robotic welding cells and be compliant with RIA standards. The company also attempts to adhere to OSHA guidelines through these recent updates to the Defender.

The product is also made to contain fumes, sparks, smoke, mist, flying debris, excess noise, and other common manufacturing process by-products, so that it can be used for robotic welding cells, automated assembly, and palletizing/packing machinery. Additionally, the roll-up design is meant to leave a minimal footprint into the typically crowded manufacturing cell.

The Defender automated barrier door features:

• PLe hold-down mechanism, which is made to lock the door in “down” position to allow for machine “de-energizing” time.

• Redesigned rotary cam limit switch, encoder positioning, and variable frequency drive, meant to control the curtain’s operating speed and position, to improve the adjustability of door position, speed, and control.

• Non-contact interlock switches, manufactured by Jokab, Pilz, Schmersal, and Allen Bradley. These are designed to provide up to PLe specifications per EN ISO 13849-1 when integrated properly.

• A design with ISO 13849-1 specification and EN 10218-2 specifications in mind.

Rite-Hite Machine Guarding hopes the Defender will appeal to a wider variety of industries—new manufacturing processes and industrial applications including conveyors, industrial elevators, and palletizing applications—than they have reached before. Additionally, the Defender is meant to be an alternative to light curtains and area scanners, going the extra step to contain the process, according to the the company.

Companies in this product