This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

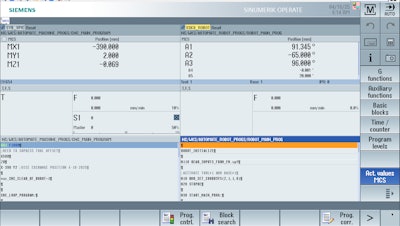

Siemens showcases a digital twin of the software and programming of its SINUMERIK 828 CNC, working in tandem with a KUKA robot, to simplify the operation and programming in part handling for the operator.

Advantages of this development include:

As automation continues to impact the machine tool industry, robots and CNC machines are collaborating closely. The number of handling and machining robots (machine tools with robotic kinematics) is on the rise and Siemens is an automation manufacturer that equips its CNC with the necessary interfaces for robotic integration.

More machine shops and operators are seeing that automation is an important asset when striving to achieve consistent workpiece quality and more flexibility on the shopfloor. Digitalization facilitates the higher level of automation needed and the networking of the components involved. With this new development, Siemens is offering a cost-effective solution that incorporates the KUKA robot functionality with a line of affordable machine tools, in this case, the SYIL brand of machining centers and lathes for small to medium job shops.

Tiansu Jing, Product Manager, SINUMERIK CNC systems, said: “The benefits of this development for the busy job shop are many. Setup, programming, operator interface and diagnostics are all improved with this system, as it easily incorporates the KUKA robot with the machine tool.”

The teach-in functions are implemented through the SINUMERIK Operate system on the control, while the proprietary SINUMERIK Run MyRobot capability of the CNC integrates with the KUKA robot control. He further noted that, since there is no need to learn robotic programming, start-up time is reduced and the robot’s separate control pendant is eliminated, making the operator’s task simplified. The SINUMERIK CNC’s HMI is used to operate both the machine tool and the robot.

From the KUKA perspective, Ron Bergamin, Key Technology Manager, Machine Tool Automation, said: “KUKA offers machine tool builders and end-users alike the ability to incorporate advanced robotics into their equipment and onto their shopfloors, with the goal of optimizing productivity and reducing operator workload. Our partnership with Siemens has resulted in the synergy that brought this development to life. It substantially expands the ability of the small and medium-sized shops to utilize robotics in their work environment.”