This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

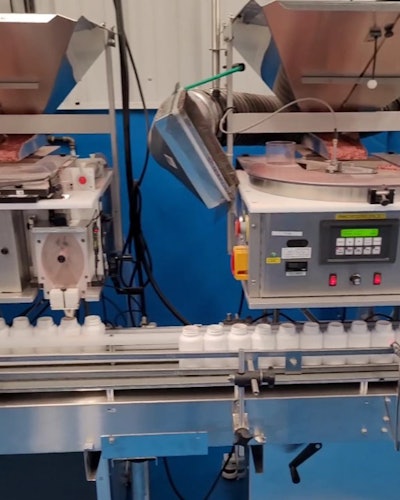

Dual lane Pharmafill CV Series conveyors from packaging machinery manufacturer Deitz Co., Wall, NJ, permit empty bottles to be automatically split from a single column into two columns for feeding two, separate tablet counting machines. Devised to double the speed of the tablet counting and filling process, the dual lane conveyors enable contract packagers and pharmaceutical and nutritional product manufacturers to achieve counting rates of up to 3,000 pills per minute with 99.99% accuracy in a tight footprint. This conveyor configuration eliminates tablet counting as a bottleneck hindering high throughputs and allows the entire filling line to operate at its optimum production speed.

Designed for sanitary processing and packaging as standard, the dual lane belt conveyors feature stainless steel construction with a food-grade acetal chain belt in a full-access setup that invites complete cleaning without any disassembly. A smooth, plastic wear strip separates the two lanes to gently guide the bottles downstream while a variable speed drive allows the conveyor speed to be quickly adjusted on the fly. The modular conveyors are available in a choice of lengths from as short as three feet to as long as 30 feet, and in custom lengths.

The motorized dual lane conveyors and automated tablet counters are designed and manufactured at the company's Wall, New Jersey headquarters. Testing is offered on the company's in-house testing and training line.