Compressed air plays an integral role in food and beverage processing and packaging. From drying materials after cleaning to blowing crumbs and debris off surfaces to opening bags for easier filling, compressed air must be free of contaminants. Keeping air dry and moisture free is crucial to ensuring it is sterile.

Yet, water and oil can be present in compressed air systems, potentially introduced by the air compressor itself. Bacteria can feed on water and oil and propagate into the crevices of compressed air lines. In addition, oil and water biofilm can seep downstream and clog or permanently degrade parts of the food manufacturing and packaging processes.

Colter Marcks, a lead development engineer for the Donaldson Company, a manufacturer of filtration products, shares some tips and tactics on how to prevent the introduction of moisture risks in your plant.

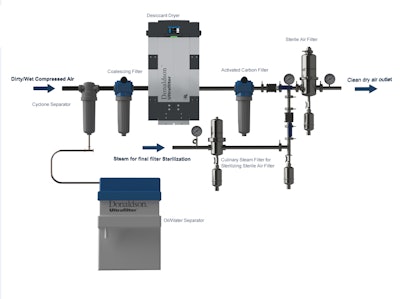

Sequence of filtration and drying steps

All compressed air systems will have a water problem starting in the compressor room. Only the volume of humidity varies with ambient air conditions and seasonal weather or climate.

Refrigerated dryers chill the air and remove bulk moisture produced during condensation, but significant liquid content can remain. Marcks recommends a sequence of treatments with various filters to remove progressively smaller liquid particles.

He says a cyclone separator spins out the bulk of the moisture remaining after the refrigerated dryer. Next, the coalescing filter combines tiny droplets into large ones that can be drained away. In the final step, the adsorption air dryer removes the remaining vapor.

Marcks particularly recommends investing in a high-quality adsorption dryer. As important as it is to capture contamination, it’s just as important to dry the air so bacteria cannot thrive in it downstream. An adsorption dryer performs this step. The adsorption dryer also provides clues to the performance of earlier steps. If you detect a higher-pressure dew point than expected, for example, the cyclone separator or coalescing filter might not be adequately removing water.

Each component in the filtration and drying process should be carefully selected and sized for your source air humidity and processing requirements.

Design for prevention

While it’s ideal to design and install all components during a new plant construction or remodel, improvements also can be made on existing lines, according to Marcks.

As you develop a plan, he recommends placing the coalescing filter and dryer as close to your production line as possible. Then, wherever process air contacts your product, use a fine micron filter at each point. Fine fiber filters here address surviving microorganisms and contaminants, such as metal flaking or corrosion, introduced by your system.

Your facility’s layout also matters, Marcks says. For example, if your facility routes cooled air from your compressor room through outdoor piping and different air temperatures, condensation may occur that needs to be removed once again.

Finally, account for fluctuating weather conditions where your facility is located, according to Marcks. In regions with high humidity or significant shifts in temperature and humidity, design your equipment to the worst-case scenario to handle peak demands.

Working with an experienced compressed air filtration provider can help you determine the best moisture-control system for your manufacturing and packaging processes.