In Case You Missed It - originally published 4/23/19

According to the “2019 Flexible Packaging Assessment Report” by PMMI Business Intelligence, the continued trend for sustainable options has influenced the flexible packaging market through various methods such as 3D printing, and the use of new stains and films.

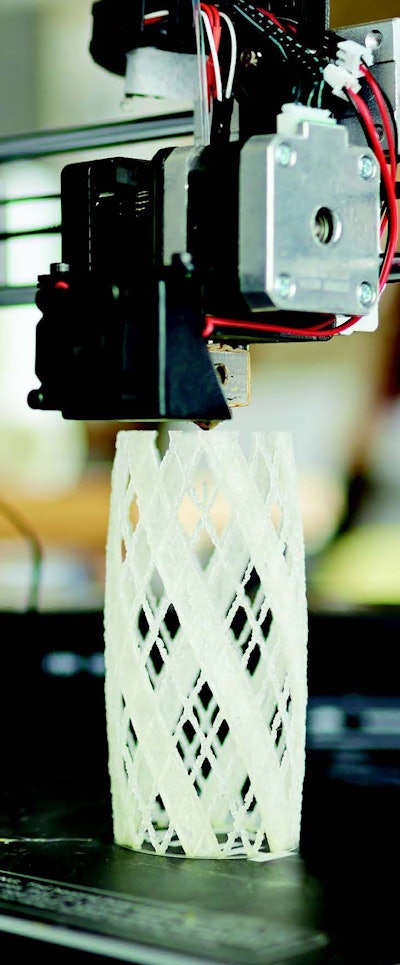

3D printing:

- Decreases cost through significantly cheaper molds.

- Packaging with eco-friendly and lightweight materials.

- Small batch production enables a faster route to market.

- Reduces flexible plastic waste pollution by re-using materials.

Stains:

New stains in flexible packaging film facilitate package breakdown (well after the end of the product shelf life), which helps the plastic degrade much faster in landfills.

Films:

- Compostable starch-based and biodegradable films.

- Consolidation to fewer films to maximize scale in order quantities.

Another method of extending the flexible packaging life cycle is to reduce the carbon footprint of packaged goods throughout the supply chain, shifting the focus from material type to packaging that uses less material. Retailers such as Costco are encouraging manufacturers to maximize warehouse space by lessening package waste, while consumers are watchful for “poorly produced, over-packaged, or non-eco substrates that package their goods.”

Download the FREE Executive Summary of this report, or, PMMI Members can download the entire report here.

Source: PMMI Business Intelligence, 2019 Flexible Packaging Assessment Report.

In Case You Missed It - originally published 4/23/19

According to the “2019 Flexible Packaging Assessment Report” by PMMI Business Intelligence, the continued trend for sustainable options has influenced the flexible packaging market through various methods such as 3D printing, and the use of new stains and films.

3D printing:

- Decreases cost through significantly cheaper molds.

- Packaging with eco-friendly and lightweight materials.

- Small batch production enables a faster route to market.

- Reduces flexible plastic waste pollution by re-using materials.

Stains:

New stains in flexible packaging film facilitate package breakdown (well after the end of the product shelf life), which helps the plastic degrade much faster in landfills.

Films:

- Compostable starch-based and biodegradable films.

- Consolidation to fewer films to maximize scale in order quantities.

Another method of extending the flexible packaging life cycle is to reduce the carbon footprint of packaged goods throughout the supply chain, shifting the focus from material type to packaging that uses less material. Retailers such as Costco are encouraging manufacturers to maximize warehouse space by lessening package waste, while consumers are watchful for “poorly produced, over-packaged, or non-eco substrates that package their goods.”

Download the FREE Executive Summary of this report, or, PMMI Members can download the entire report here.

Source: PMMI Business Intelligence, 2019 Flexible Packaging Assessment Report.

In Case You Missed It - originally published 4/23/19

According to the “2019 Flexible Packaging Assessment Report” by PMMI Business Intelligence, the continued trend for sustainable options has influenced the flexible packaging market through various methods such as 3D printing, and the use of new stains and films.

3D printing:

- Decreases cost through significantly cheaper molds.

- Packaging with eco-friendly and lightweight materials.

- Small batch production enables a faster route to market.

- Reduces flexible plastic waste pollution by re-using materials.

Stains:

New stains in flexible packaging film facilitate package breakdown (well after the end of the product shelf life), which helps the plastic degrade much faster in landfills.

Films:

- Compostable starch-based and biodegradable films.

- Consolidation to fewer films to maximize scale in order quantities.

Another method of extending the flexible packaging life cycle is to reduce the carbon footprint of packaged goods throughout the supply chain, shifting the focus from material type to packaging that uses less material. Retailers such as Costco are encouraging manufacturers to maximize warehouse space by lessening package waste, while consumers are watchful for “poorly produced, over-packaged, or non-eco substrates that package their goods.”

Download the FREE Executive Summary of this report, or, PMMI Members can download the entire report here.

Source: PMMI Business Intelligence, 2019 Flexible Packaging Assessment Report.