This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

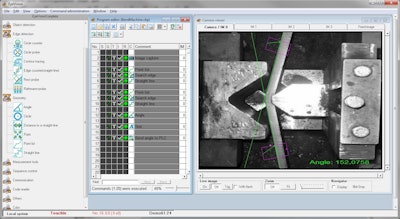

The sensor reports to the control of the bending machine the exact bending angle 30 times per second. Therefore it is guaranteed that the angle matches exactly the preset values.

The powerful interfaces also allow the sensor to be easily integrated into the existing bending machines and by that extend the life time cycle of the machine. Also it is possible to adapt to the growing requirements in the modern production.

With the new EyeSens vision sensor series now very powerful smart cameras with selected commands of the EyeVision image processing software for easy programming and fast evaluation of the inspection tasks, are available for the user. The systems now also have a higher resolution: the EyeSens sensors are not only available in the resolution 782 x 485 pixel but also as EyeSens HR with 1024 x 768 pixel and as EyeSens XHR with a resolution of 1280 x 1024 pixel. Additionally the sensors are equipped with an integrated illumination (8 LEDs) and lens with 6, 12 or 25 mm focal length.

Additionally, there is also a C-Mount version available.

The new EyeVision 3.0 image processing software also supports now not only European languages but also:

Japanese

Chinese (Mandarin)

Korean

The configuration interface is available for Windows up to version 8 as well as for Linux and Mac OSX. For each application – from simple measurement up to high-speed image processing solutions – EyeVision 3.0 offers the suitable commands. The programming of inspection programs is easy even for user without programming skills, due to the drag-and-drop function in the configuration mode. The more advanced user can also program with the integrated script interpreter.