This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

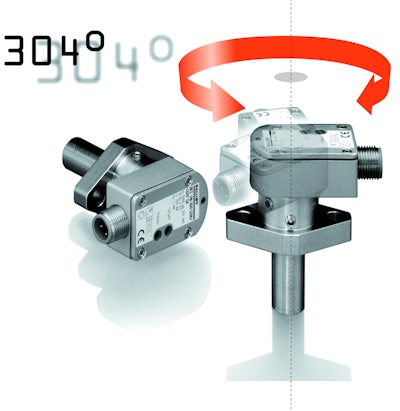

The sensor housing allows 304° of rotation that eliminates the hassle of post installation cable adjustments. This rotating feature also eliminates the need to unbolt the flange from the cylinder and breaking the seal.

A high-pressure, inductive proximity sensor, the Strokemaster provides a 2mm (0.08”) sensing range to detect the “spud” of hydraulic/pneumatic cylinders which indicates fully retracted or extended position. It mounts with just two screws, and seals with an O-ring. Withstanding cylinder pressures to 3000 psi (207 BAR), the embeddable design keeps most of the switch protected within the cylinder, with only a 0.62” (16 mm) high housing exposed outside. The rotating housing can be locked in any desired position with either one of two set screws.

Strokemaster sensors are available in 3-wire DC and 2-wire AC/DC versions, both with mini or micro connectors. Switching frequency is 50 Hz for the AC/DC versions. All units are weld-field immune, short-circuit, and reverse-polarity protected. They fit all popular cylinder designs, with standard probe lengths of 0.912” - 4.560” (23.165mm - 115.8mm). Custom probe lengths can be achieved by using spacer kits. Probes are made of stainless steel with a ceramic face. Both DC and AC/DC sensors have all metal housings.