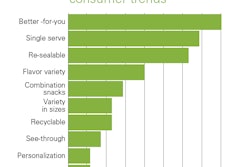

According to a new report by PMMI Business Intelligence, the U.S. flexible packaging market was valued at approximately $24 billion in 2016. The global market was valued at $98 billion, with an expected compound annual growth rate (CAGR) of 5.2 percent between 2017 and 2022. While the global flexible market is still smaller than global rigid, it is growing at a faster rate.

Flexible packaging has benefits such as being better suited for printing - making it a great marketing tool; having a lower space footprint than similar rigid packages; and, providing a longer shelf life if multi-layered films are used.

According to one packaging manager at a tortilla chip co-packer, growth of “unique types of flexible packages” has been pronounced in recent years, including a stand-up pouch explosion (especially the zippered kind).

According to an OEM case study, there is a move from bag in-box (BIB) to bag, with benefits such as cost savings, efficient/sustainable material usage and machinery savings (no need for a cartoner). One example is Ritz Toasted Chips.

Food segments that are traditionally BIB (e.g. cereals) are making this transition, especially for high-end products like granola cereals. For snacks, the transition has started with crackers (other categories to follow).

To meet these changes, demand for flexible vertical form/fill/seal machines will be high in the coming years, as CPGs like the smaller footprint and the associated space-saving. However, VFFS machines must improve in terms of flexibility; as respondents feel that currently they do not run stand-up pouches well enough - zippered or unzippered.

Source: PMMI Business Intelligence “Snack Foods – Packaging and Processing Market Assessment and Trends 2018”

For more details about the Snack Foods market as it pertains to the packaging and processing industry, download the FREE Executive Summary or the full report here.

According to a new report by PMMI Business Intelligence, the U.S. flexible packaging market was valued at approximately $24 billion in 2016. The global market was valued at $98 billion, with an expected compound annual growth rate (CAGR) of 5.2 percent between 2017 and 2022. While the global flexible market is still smaller than global rigid, it is growing at a faster rate.

Flexible packaging has benefits such as being better suited for printing - making it a great marketing tool; having a lower space footprint than similar rigid packages; and, providing a longer shelf life if multi-layered films are used.

According to one packaging manager at a tortilla chip co-packer, growth of “unique types of flexible packages” has been pronounced in recent years, including a stand-up pouch explosion (especially the zippered kind).

According to an OEM case study, there is a move from bag in-box (BIB) to bag, with benefits such as cost savings, efficient/sustainable material usage and machinery savings (no need for a cartoner). One example is Ritz Toasted Chips.

Food segments that are traditionally BIB (e.g. cereals) are making this transition, especially for high-end products like granola cereals. For snacks, the transition has started with crackers (other categories to follow).

To meet these changes, demand for flexible vertical form/fill/seal machines will be high in the coming years, as CPGs like the smaller footprint and the associated space-saving. However, VFFS machines must improve in terms of flexibility; as respondents feel that currently they do not run stand-up pouches well enough - zippered or unzippered.

Source: PMMI Business Intelligence “Snack Foods – Packaging and Processing Market Assessment and Trends 2018”

For more details about the Snack Foods market as it pertains to the packaging and processing industry, download the FREE Executive Summary or the full report here.