In the snack food industry, e-commerce of snacks sold online via retailers such as Amazon or Walmart and delivered to the home, is showing fast growth in the US. According to “Snack Foods – Packaging and Processing Market Assessment and Trends 2018,” a new white paper by PMMI Business Intelligence. This growth has shown a strong influence on packaging, say both large and medium-sized CPGs.

“We are in negotiations with retailers regarding producing 2-3 count cases specifically for e-commerce,” said one packaging purchasing manager of a nuts manufacturer.

The goal of “online-ready” packaging is to create minimum re-packing effort (if any) for online retailers through the use of smaller cases, lower case counts, easier to open cases or smaller multi-packs.

Another market trend mentioned by brand owners in particular and driven by retailers such as Walmart and Kroger, is Shelf Ready Packaging (SRP).

Benefits of SRP include reduced unpackaging costs such as labor and inventory management, and the marketing and brand promotion that comes from the graphics displays on the cases. There are also many types of SRP, which puts significant pressure on secondary packaging flexibility.

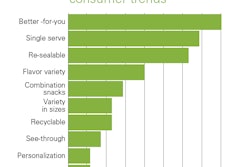

Source: PMMI Business Intelligence “Snack Foods – Packaging and Processing Market Assessment and Trends 2018”

For more details about the snack foods market as it pertains to the packaging and processing industry, download the FREE Executive Summary or the full report here.