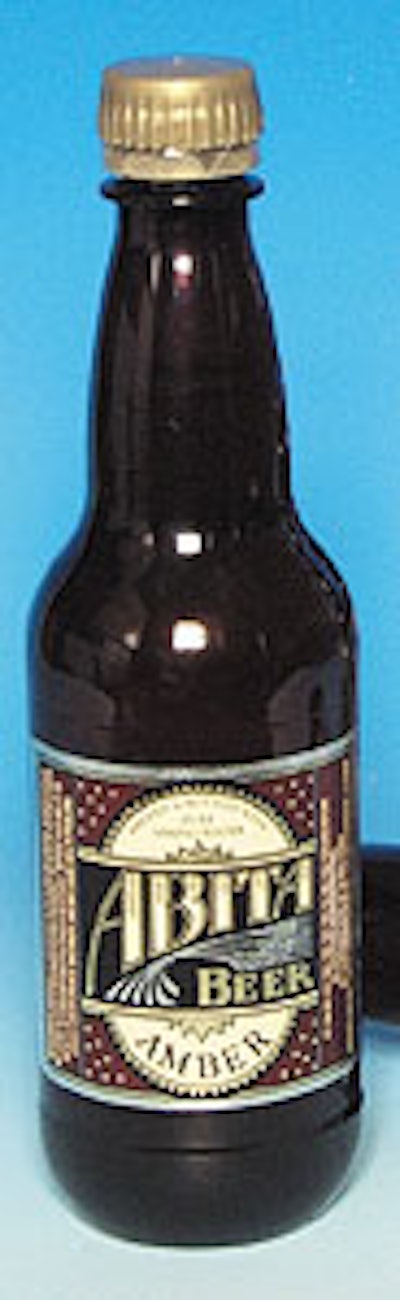

It plans to introduce 16-oz bottles of its top-selling “Amber”-brand beer early next year “for special events, arenas, and future Mardi Gras celebrations,” relates CFO Patrick Gernon. “This will be our first venture into plastic beer bottles. It lets us get into venues where we couldn’t previously.”

Constar, a subsidiary of Crown Cork & Seal (Philadelphia, PA), makes the new bottle, which it says withstands 35 “pasteurization units,” defined as the equivalent of 60°C (140°F) for one minute for beer. Constar incorporates its patented Oxbar™ oxygen scavenger layer between two heavier PET layers. The scavenger uses MXD-6 nylon and a catalyst that Constar says yields an oxygen transmission rate it describes as 0.5 microliters/bottle/ 24 hr. Constar co-injection molds preforms, and then stretch blow-molds them into bottles. Specialized injection-molding tooling from Kortec (Beverly, MA) plays a critical role.