In recent years, the consumer packaged goods community has proved eager to embrace new feedstocks to replace petroleum-based plastics and virgin paper fiber. Sugarcane, corn, mushroom roots, limestone, potato starch, recycled jute sacks, and even sheep’s wool are among some of the materials currently being used in packaging. Now, French champagne producer Veuve Clicquot has added to that list, using an organic byproduct of its own winemaking process: grapes skins.

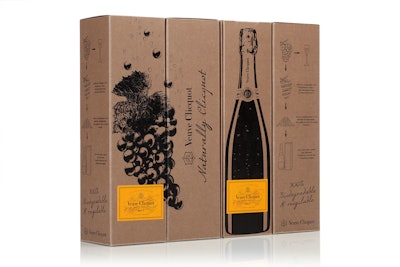

In September 2015, the firm introduced Naturally Clicquot 3 in a secondary carton made from a combination of water, natural fibers, and grape skins that reduces the use of virgin fiber by 25%. The package is version 3.0 of the company’s Naturally Clicquot packaging evolution. Naturally Clicquot 1 and 2 were designed as isothermal, biodegradable secondary packages made from potato starch and paper.

The material for version 3.0 is produced especially for Veuve Clicquot by Favini, an Italian company experienced in the manufacture of agro-industrial waste-based paper. Favini’s Crush line of eco-friendly papers is made in part from the residue of fruits and nuts such as oranges, kiwis, cherries, almonds, hazelnuts, and coffee.