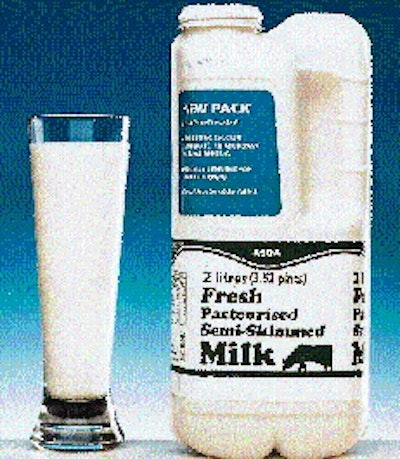

One of the division's first projects is a field trial of the Tetra Max bottle (see PW, December '95, p. 64), undertaken with MD Foods, a dairy in the northern English town of Newcastle, and ASDA, a U.K. chain of 200-plus supermarkets. The bottle is made of a filled polypropylene (which Tetra calls TPRX) supplied by Filltech, a Tetra subsidiary in the Netherlands. The chief benefit of the material is that, unlike a bottle extrusion-blown of high-density polyethylene, a bottle made of TPRX crushes flat and stays flat in the garbage can. This, says Tetra, reduces wasted space in the solid waste stream. Tetra also claims the bottle "consumes less energy and lower quantities of fossil fuels than [other] plastic bottle alternatives." Recycling tests, says Tetra, are underway.