This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

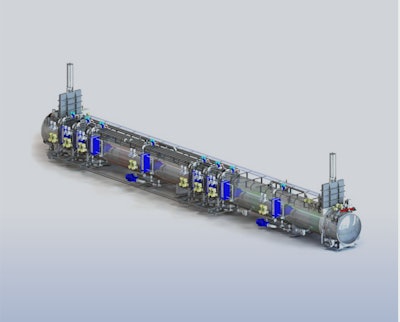

The Surdry continuous sterilizer promotes steam consumption savings between 30% and 40%. It enables the processing of cans, glass bottles, and pouches in the same retort equipment, allowing manufacturers to expand their businesses.

“We’re very excited to present our new continuous sterilizer technology at PACK EXPO this year. It was developed internally by Surdry and is a game changer for the retort industry,” says Julian Stauffer, CEO of Surdry North America. “By maintaining a continuous flow of sterilization, companies will consume significantly less energy, lowering their production costs and environmental impact. Additionally, the show is a great opportunity for attendees to learn how they can take advantage of our aftermarket program SurdryUP, which was designed to alleviate the burden of machine maintenance. It allows our customers to focus on growing their businesses.”

SurdryUP is an SNA program dedicated to minimizing unplanned machine downtime while enhancing the customer experience. With SurdryUP, every Surdry retort installed within the U.S., Mexico, and Canada is eligible to receive a free preventative maintenance analysis annually. During their visits, SNA technicians identify parts that need replacing, review inventory levels, provide maintenance recommendations, and suggest operational improvements to increase performance and safety.