When it comes to low-moisture foods production, consumer packaged goods (CPG) manufacturers have a goal of using equipment to minimize the risk of food contamination. The original equipment manufacturers (OEM) have a goal of building that equipment in a competitive environment and offering a streamlined number of options that are profitable. Obviously, it takes collaboration between CPGs and OEMs to achieve these mutual goals. And that’s exactly what PMMI’s OpX Leadership Network’s Engineering Solutions Group had in mind when it developed a work tool called One Voice for Hygienic Equipment Design for Low-Moisture Foods.

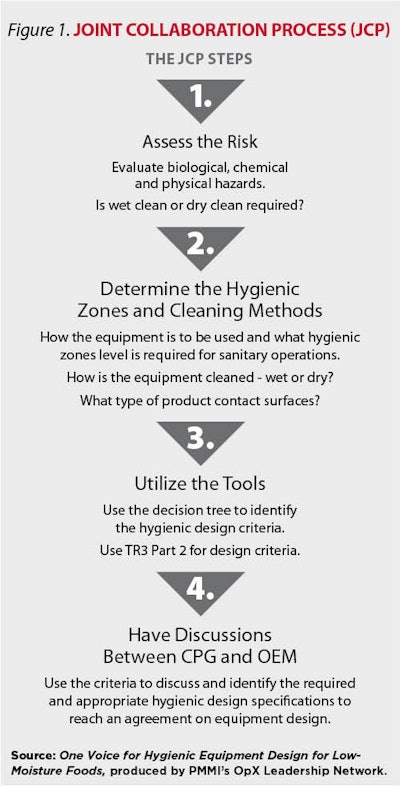

In the first part of the two-part work tool document, the focus is on a joint collaboration process (JCP) between CPGs and OEMs that enables them to get on the same page regarding the design and construction of equipment for the production of low-moisture foods. Figure 1 features four critical steps to the JCP:

• Assess the risks by evaluating the biological, chemical and physical hazards utilizing the ANSI/PMMI iterative process for risk assessment.

• Determine the hygienic zones and cleaning method by identifying how the equipment will be used and what hygienic zone level is required for sanitary operations, as well as type of product contact surfaces and how equipment is to be cleaned.

• Utilize the tools in this document, including the “Equipment Hygiene Level Decision Tree for Low-Moisture Foods” in Part 1 and the “Criteria for the Design and Construction of Equipment Used to Manufacture Low-Moisture Foods” in Part 2.

• Have discussions between CPGs and OEMs to reach an agreement on the design and construction of the equipment.

Balancing capital and risk when purchasing equipment

As shown in Figure 2, the JCP can help CPGs and OEMs identify and agree on the minimum requirements for equipment to meet food safe design for the manufacture of low-moisture foods. It encourages greater collaboration both within the CPG and the OEM and between them as well. It invites more stakeholders into the decision-making process for both, including operations, engineering, procurement, quality, sanitation, etc. Most importantly, it makes existing knowledge, guidelines and standards easier to apply in fabrication and manufacturing.

One of the most significant ways the JCP can help is in determining the best value option that balances capital and risk for CPGs to consider when purchasing equipment for the manufacture of low-moisture foods. Figure 3 shows the options to be considered, ranging from the base model with the lowest delivered costs to add-ons for easier cleaning and maintenance and more add-ons for wet clean, smooth surfaces, stainless, hot water and acid-resistant surfaces.

To learn more about the One Voice for Hygienic Equipment Design for Low-Moisture Foods tool from PMMI’s OpX Leadership Network and how to use it, download it for free at www.opxleadershipnetwork.org.

Learn how Campbell Soup applies the tool by reading "Helping Campbell’s with continuous improvement."