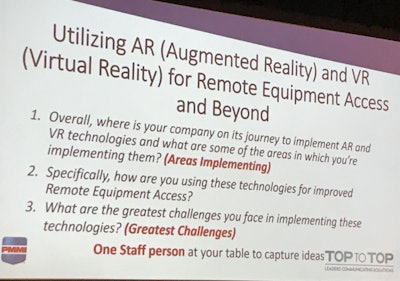

At PMMI’s exclusive Top to Top meeting held this week, a panel consisting of two forward-thinking brand owners and another like-minded packaging machinery OEM ticked off a laundry list of best practices, hurdles, and solutions for deploying the technology.

“I had been monitoring the technology, but the tipping point for me was that the form factor for certain types of glasses [Vuzix in this case] finally matched what would otherwise be typical safety glasses,” one brand owner says. “The moment I saw that, I thought, ‘OK, it’s ready for production since we wear safety glasses anyway.”

Still, he warned, it will change again within six months, and again a few months after that. The speed at which the AR/VR technology is developing across the industry means that it quickly becomes obsolete. But for early adopters, being ahead of the curve has been worth the constant treadmill of keeping up with new features and capabilities.

The brand owner described an FAT that was to be held halfway around the world. Only a fraction of the team needed to go, while the remaining team members stayed home, but were visually and audibly patched in, via the AR 3D space, to accompany the field team on the FAT. He said those cost savings paid for their fledgling AR/VR program then and there, upon first use.

Content creation burden

The benefit in terms of live troubleshooting or live remote FAT/SAT support obviate themselves. But more sophisticated uses may require more input, such as developing and maintaining documentation and content in the form of instruction manuals, video troubleshooting, etc. that’s to be made available via the headpiece/hardware. This takes time and effort to develop, but the other brand owner who implemented this tech mentioned an unforeseen benefit. He was forced to clean, refresh, and update an old and disorganized instruction-style content. Having such documents available at the touch of the AR glasses means they’re more regularly consulted – content obsolescence was recognized and eliminated.

The same brand owner uses the AR/VR glasses in conjunction with QR codes located throughout processing and packaging machines in his plant. The QR codes carry pertinent information such as safety instructions, red/yellow/green status, live data for temperature, speed, vibration, and various other KPIs related, in real time, at a glance of someone wearing the headset. Again, that means there’s some back-end work in keeping the associated information, safety standards, and other content updated and available. This brand owner is still working on developing a training program with courses that new hires can take with the AR/VR headset, as well.

What brand owners want to use it for is a thornier issue, and the following issues continue to hamper long term adoption:

- There are a lot of different formats, software, and levels of sophistication. As different OEMs choose or standardize on different formats, that means CPG customers, who have many different OEM supplier partners, may be forced to learn many different AR/VR formats. [Note: One OEM that serves several industries indicated they support 85 formats including digital]

- Sometimes the technology is more than you need – will a simple video do the job? This could be a both/and situation in which the troubleshooting video is part of the AR/VR content. When the pre-loaded video doesn’t do the job, the same headset that shows the video can also remotely connect to a maintenance person in another state or an OEM for service or remote diagnostics.

- Remote diagnostics themselves are an issue and evokes the larger IT/OT divide. Will a CPG allow video from live production to exit the four walls of the plant? Will they even allow a cell phone in to provide a hotspot?

- Battery life is currently around two hours when the headset is completing heavy lifting like sharing video remotely but can extend to eight hours when completing more mundane tasks.

For OEMs, the potential benefits are clear. CPG and brand owner adoption, based largely on uncertainty around remote access, seems to be the largest stumbling block. Here are a few potential benefits to OEMs:

- Instead of sending two people to a service call, one experienced, and one junior to learn, the junior could go alone knowing that experienced reinforcement can remote in.

- Remote training and troubleshooting remotely.

- Custom machinery builders can use the platform to constantly course correct and maintain contact with the end user throughout the project, making adjustments on the fly and reducing rework. “They can see what we’re doing through our eyes, so they don’t have to send someone every time there’s an alteration on the design – we can show them remotely,” the OEM says.

The question then becomes whether the CPG or the OEM should ‘own’ the platform. Many vendors with many platforms, as has been mentioned, maybe a hurdle that prevents end-user adoption.

Should CPGs, then, take the lead on ‘owning’ the AR/VR platform and sharing it with (or specifying it to) their machinery or controls/components vendors? Usually, the expense occurred by CPGs would make this a non-starter, but the low barrier to entry as far as AR/VR cost may make this realistic. And not only realistic, but it could also be practical in preventing yet another situation in which many OEMs develop their own disparate, proprietary AR/VR programs, with CPGs and brand owners having to learn many different formats from all their vendors. The coming years will probably decide where the balance of platform ‘ownership’ falls: the OEM or the end user of the equipment.

More: Here is a smattering of other pragmatic tips for starting an AR/VR program, wherever you stand on the supply chain:

1. College campus experiment

An adage about college campuses juxtaposes the paved walkways that represent the planned routes with the worn foot trails and shortcuts through the grass that appear on college campuses. The former lead were planners aimed to have people walk, the latter represented where students actually walked.

The brand owner panelist elicited this dynamic while presenting to impress upon attendees that implementation should be a function of addressing a need rather than implementing for the sake of implementing.

“We set up people to walk one way only to discover they want to walk somewhere else,” he says. “You don’t want that to happen with your AR/VR program. Start using it, but wait and watch to see where people want to use it, where people find value in it, rather than dictating it be used when it might be a square peg in a round hole. Don’t pick the tool and then go try to find the problem. And don’t use the tool to try to solve the problem you think they have. Instead, throw it out there and see what they do. Let the uses develop organically, then build on that. Adoption will improve because the application will be theirs based on their needs, not what you think they need.”

2. Engage an AR/VR champion

Simply using the technology is easy – five minutes out of the box is all it takes to be remotely recording and sharing content. “We were shocked by how simple it was to set up,” says one of the brand owners. He also pointed to the fact that the it’s a technology that tends to excite millennials—plus, thanks to video games and other electronic experiences they grew up with, AR/VR is a space they’re naturally familiar with in ways previous generations might not be. So, implementation can be an engaging responsibility for the right type of person.

3. Beware one-size-fits-all approach from vendors

Currently, AR/VR headsets are deployed across the industry, including everything from oil and gas to gaming. Be sure you’re working with someone who understands your needs and knows they are quite different from others to avoid costly upcharges for features you don’t need.