The study, “Robots 2019: Innovation 2 Implementation,” also says that Artificial Intelligence (AI) is on the threshold of wider adoption. Only 11% of the 721 participants in an earlier poll reported using AI in their processing and packaging equipment currently.

But “…the future of autonomous robots is fast approaching,” says Paula Feldman, Director of Business Intelligence for PMMI. Manufacturing plants of tomorrow will utilize AI powered robots capable of learning a variety of tasks, adapting to a changing environment, and operating from a single, unified controls system. These robots promise to be:

- Mobile: Robots and cobots that are untethered and wireless with 7th axis mobility creating a flexible manufacturing environment.

- Intelligent: Smart robotics equipped with sensors feeding data to complex algorithms powering AI and machine learning to improve processes.

- Perceptive: 3D vision is able to recognize objects with greater precision and accuracy to perform repetitive tasks, freeing up humans for elevated responsibilities.

Agile: Work station assistants with arm-like EOAT (end of arm tooling) dexterity capable of learning and performing a large number of tasks alongside human labor.

“There are new robot technologies in the works that researchers are not yet willing to share, but indicate a drive toward smaller components and smarter learning skills,” says one Sr. Robotics Applications Engineer at an OEM.

“The trend is to make all automation, including robotics, easier to use in general, like a smartphone,” says a Director of Engineering for a robot manufacturer.

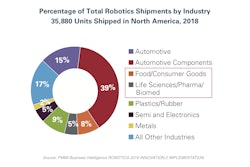

Deployment of robotics in North America in the food and consumer goods segment reported record setting growth of a 47.6% increase in the number of units shipped from 2017-2018 (total 2,946). In addition to this, a 31.3% increase in units shipped also occurred in the life sciences/pharma segment during the same time period (total 1,714), the report quotes Robot Industry Association stats.

Download your FREE 9-page Executive Summary, or, PMMI Members can download the entire 63-page report for free here.

Visit PACK EXPO Las Vegas September 23-25 to see dozens of robots in action, both stand-alone and integrated into packaging machinery as well as the Future Innovators Robotic Showcase.

The study, “Robots 2019: Innovation 2 Implementation,” also says that Artificial Intelligence (AI) is on the threshold of wider adoption. Only 11% of the 721 participants in an earlier poll reported using AI in their processing and packaging equipment currently.

But “…the future of autonomous robots is fast approaching,” says Paula Feldman, Director of Business Intelligence for PMMI. Manufacturing plants of tomorrow will utilize AI powered robots capable of learning a variety of tasks, adapting to a changing environment, and operating from a single, unified controls system. These robots promise to be:

- Mobile: Robots and cobots that are untethered and wireless with 7th axis mobility creating a flexible manufacturing environment.

- Intelligent: Smart robotics equipped with sensors feeding data to complex algorithms powering AI and machine learning to improve processes.

- Perceptive: 3D vision is able to recognize objects with greater precision and accuracy to perform repetitive tasks, freeing up humans for elevated responsibilities.

Agile: Work station assistants with arm-like EOAT (end of arm tooling) dexterity capable of learning and performing a large number of tasks alongside human labor.

“There are new robot technologies in the works that researchers are not yet willing to share, but indicate a drive toward smaller components and smarter learning skills,” says one Sr. Robotics Applications Engineer at an OEM.

“The trend is to make all automation, including robotics, easier to use in general, like a smartphone,” says a Director of Engineering for a robot manufacturer.

Deployment of robotics in North America in the food and consumer goods segment reported record setting growth of a 47.6% increase in the number of units shipped from 2017-2018 (total 2,946). In addition to this, a 31.3% increase in units shipped also occurred in the life sciences/pharma segment during the same time period (total 1,714), the report quotes Robot Industry Association stats.

Download your FREE 9-page Executive Summary, or, PMMI Members can download the entire 63-page report for free here.

Visit PACK EXPO Las Vegas September 23-25 to see dozens of robots in action, both stand-alone and integrated into packaging machinery as well as the Future Innovators Robotic Showcase.

The study, “Robots 2019: Innovation 2 Implementation,” also says that Artificial Intelligence (AI) is on the threshold of wider adoption. Only 11% of the 721 participants in an earlier poll reported using AI in their processing and packaging equipment currently.

But “…the future of autonomous robots is fast approaching,” says Paula Feldman, Director of Business Intelligence for PMMI. Manufacturing plants of tomorrow will utilize AI powered robots capable of learning a variety of tasks, adapting to a changing environment, and operating from a single, unified controls system. These robots promise to be:

- Mobile: Robots and cobots that are untethered and wireless with 7th axis mobility creating a flexible manufacturing environment.

- Intelligent: Smart robotics equipped with sensors feeding data to complex algorithms powering AI and machine learning to improve processes.

- Perceptive: 3D vision is able to recognize objects with greater precision and accuracy to perform repetitive tasks, freeing up humans for elevated responsibilities.

Agile: Work station assistants with arm-like EOAT (end of arm tooling) dexterity capable of learning and performing a large number of tasks alongside human labor.

“There are new robot technologies in the works that researchers are not yet willing to share, but indicate a drive toward smaller components and smarter learning skills,” says one Sr. Robotics Applications Engineer at an OEM.

“The trend is to make all automation, including robotics, easier to use in general, like a smartphone,” says a Director of Engineering for a robot manufacturer.

Deployment of robotics in North America in the food and consumer goods segment reported record setting growth of a 47.6% increase in the number of units shipped from 2017-2018 (total 2,946). In addition to this, a 31.3% increase in units shipped also occurred in the life sciences/pharma segment during the same time period (total 1,714), the report quotes Robot Industry Association stats.

Download your FREE 9-page Executive Summary, or, PMMI Members can download the entire 63-page report for free here.

Visit PACK EXPO Las Vegas September 23-25 to see dozens of robots in action, both stand-alone and integrated into packaging machinery as well as the Future Innovators Robotic Showcase.