Sizable CapEx plant spending on equipment and advanced automation in the dairy industry is well underway. Industry leaders like Chobani have caught the attention of consumers, and the dairy industry itself has been in the spotlight due to its aggressive monitoring and optimization effort across the enterprises (see related story on Chobani reveals its secret for better production data visibility).

Furious innovation — and investment — is producing dividends as plants target different processes within dairy processing facilities. Dairy producers are currently identifying better efficiencies for the "standardization process" of fats, proteins, solids non-fat and total solids. Milk standardization takes those components, such as fat, that have previously been separated from a product, and then are added back into that product in precise or standardized quantities.

Plant strategies for better milk standardization efficiencies can include newer inline equipment connected to the entire process, such as the separator, valves and other equipment. Moving to an inline approach allows producers to shift away from inflexible, batch standardizing that necessitates long buffer times with fat or protein yield (meaning the entire product batch needs to discharge from the pasteurized tank).

Commissioning of inline, dairy standardization equipment also avoids disruption to a plant production schedule. “We had about three days to install a new standardized system that would replace three, obsolete pieces of equipment,” says Josette Bogerman, regional project manager at Arla Foods in the United Kingdom.

For Arla Foods’ Palmers Green dairy application, Tetra Pak supplied the new standardization equipment, allowing the food producer to run its milk fat setpoint at 3.0% and have it come in at +/- 0.015% of the setpoint.

Before the addition of this new equipment, operators took samples and then adjusted the fat content accordingly. “Now we always know what’s in the tank and operators trust what they read on the screen is in the tank,” says Bogerman. Our plant operators also favor the new equipment when it comes to short, product runs, since they are difficult to standardize.”

This dairy producer processes about 1.2 million liters daily and has a large number of clients. “Different customers demand that their milk is processed separately,” says Bogerman. We deal with enormous amounts of product changeovers and segregation, and this gives us less time for standardization in the tanks.”

Other approaches for dairy standardization in the industry include tighter integration into a plant’s main control system — via industrial networks — to provide better alarm information to operators. “Operators can now anticipate process disturbances and can actually 'freeze' control valves around the standardization process,” says Scott Young, dairy consultant for system integrator Maverick Technologies in recent webinar. “Otherwise, the recovery time for producing product within specifications after a process disturbance, like a separate or desludge, will take longer.”

Australia-based Fonterra Dairy, a large global dairy processor produces more than 22,500 tons of milk powder products annually from 250 million litres of milk at its site in Dennington. Recently, the company installed Rockwell Automation’s Pavilion 8 Model Predictive Control (MPC) to optimize the plant's standardization process into its main control system.

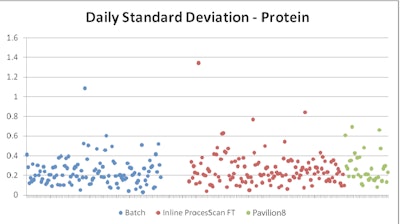

This model predictive control platform — hardware and software — continuously monitors and controls multiple production variables and compares the current performance to optimum setpoints. Once the predictive system models the plant's multiple applications, the control system optimizes production continuously.

The Dennington facility moved from a batch to a predictive control approach, and the plant reduced protein giveaway by 49%. Other bottom-line results included a 38% reduction for fat annually while saving close to $685,300 in the first year of operation with this new automation approach.

“Most of the time the customer will use their current control system with the instrumentation in place, as well. If not, we'll make some recommendations to include that in ROI calculations," says Lance Rodenfels, dairy solutions expert at Rockwell Automation in the webinar. We usually target one year to year and a half return with the MPC optimization platform.”