Chelsea Milling has incorporated a new AI system intended to eliminate manual processes and improve ingredient safety and compliance. The Intelligent Document Processing (IDP) system, from Colorado-based TraceGains, offers material compliance and lot-level ingredient quality control. Purpose-built to streamline certificate of analysis (COA) processing to ensure a product's compliance in terms of quality, performance, and safety. TraceGains says its IDP eliminates the need for manual processes while improving accuracy and operational efficiency across workflows for the maker of Jiffy Mix.

"We designed IDP to deliver superior accuracy and reliability by continuously learning and improving with every use," says Paul Bradley, Senior Director of Product Marketing, TraceGains. "Our AI-driven solution eliminates the inefficiencies of manual data verification, empowering brands to proactively manage supply chain quality and compliance. Customer feedback indicates it is a smarter, faster way to ensure the safety and integrity of the products consumers rely on."

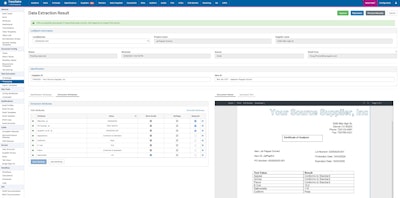

Built on OpenAI's foundation model and trained and validated against global F&B industry COAs, IDP is designed to deliver accuracy and reliability, even as COA formats evolve. Large-scale brands processing thousands of COAs monthly spend countless days and hours relying on manual inefficient and error-prone methods. TraceGains’ IDP improves the process by automatically reviewing inbound COAs against required specifications, flagging potential issues where additional human oversight is needed. In time-in-motion studies, IDP eliminated the average 12-minute per-page manual setup previously required, drastically reducing implementation times while ensuring data integrity and compliance.

“Digitizing COAs and making them actionable through TraceGains has resulted in a 75% reduction of out-of-spec lots on the receiving dock,” says Bill Besson, Quality Assurance Director at Chelsea Milling.

Vertical AI model optimized for food and beverage

In today's disparate food and beverage supply chains millions of non-standardized documents circulate annually between suppliers, manufacturers, and retailers, containing mission-critical information on ingredient specifications, food safety, allergen declarations, and sustainability data. TraceGains says its IDP leverages advancements in AI and natural language processing to extract relevant information from these non-standard documents, transforming them into structured, composable data that seamlessly integrates with TraceGains solutions and flows across the supply chain.

TraceGains says the release of its IDP represents the first vertically tailored AI-powered solution optimized for the food and beverage industry built on OpenAI trained with decades of contextual food and beverage data from TraceGains. IDP aims to provide a foundation for the future of food quality capable of addressing specialized tasks effectively, beginning with COA as the first offering.

The company says that unlike solutions based on static, zoning-based optical character recognition (OCR) technologies, IDP leverages advancements in AI to read unfamiliar and non-standard document formats with high accuracy. The system also learns over time, enhancing data extraction and accuracy as more documents are processed. Early trials demonstrate substantially higher accuracy than legacy methods, potentially matching or exceeding the accuracy of human comparison at much higher speeds, the company says.

"With the release of IDP, TraceGains is reinforcing its legacy and leadership as an F&B innovator by applying our domain expertise to advancements in AI and passing that advantage and power to customers," says Greg Heartman, Vice President, Product Management, TraceGains. "By combining our rich contextual TraceGains data with the OpenAI model, we've created a vertical-specific AI solution for brands to manage the continual quality of their supply chain and ensure consumer food safety."