Viking Kristjansson is Vice President, Sales Engineering at FoodSafe Drains.

In food manufacturing, every food safety detail matters. While surface sanitation, air filtration, and equipment hygiene are often the focus of compliance efforts, one critical factor remains overlooked: the drainage system. Traditional, outdated or poorly designed drainage systems pose significant risks to food safety and facility operations. They can harbor harmful bacteria, leading to foodborne illnesses, costly recalls, reputational damage, and operational disruptions. Clogs and floods exacerbate these issues, compromising safety and causing downtime.

Modern food-safe slot drain systems are transforming facilities by enhancing safety, hygiene, and efficiency. These systems collect fewer contaminants, are easier to clean, and reduce cleaning time, making thorough sanitation more feasible. They are also straightforward to install or retrofit, making them ideal for upgrading existing facilities. Specialized companies can complete installations quickly, often within two to three days, minimizing downtime and ensuring a seamless transition.

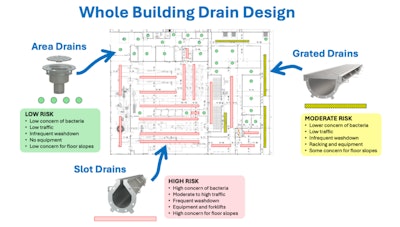

A whole-building approach to drainage, considering every aspect of a facility’s sanitation and operational needs, is essential for ensuring a safe, efficient, and regulatory-compliant environment.

Strategic approach for an entire facility

Designing an efficient drainage system for food production facilities demands a carefully tailored strategy, as there is no one-size-fits-all solution. Each area within a facility—be it a busy processing zone, a storage area, or a customer-facing space like a winery—has unique needs that call for carefully tailored solutions.

Critical considerations include contamination risks, frequency of washdowns, water flow volume, exposure to high temperatures or harsh chemicals, equipment weight, and floor slope. Even aesthetics play a role in customer-facing spaces like wineries.

There are three types of drains commonly used in food production facilities: area drains and two two types of linear drains—grated drains and slot drains. Choosing the optimal solution for each application and area is key to creating an effective system.

Food manufacturing facilities operate under strict hygiene protocols, yet drains—the very systems designed to remove waste and water—are often ignored during audits and inspections. Surprisingly, drains are rarely part of USDA audits, despite their potential to harbor dangerous pathogens like Listeria monocytogenes.

A University of Maryland fact sheet on managing Listeria highlights how drains, especially those in consistently wet areas, are prime locations for bacterial growth. Cross-contamination from poorly maintained drains can spread bacteria throughout a facility, even when all other surfaces appear sanitized. If the facility as a whole is not designed with easy-to-clean drainage in mind, the risk of contamination increases significantly.

Accessibility: area drains vs. linear drains

Area and linear drains have several design differences. Image provided by Global Drain Technologies

Traditional area drain systems present significant challenges due to their extensive underground piping, which is difficult and expensive to access and clean. For instance, in a 4,800-sq.-ft. facility, an area drain system typically includes about 244 ft. of buried pipes. These hidden pipes cannot be visually inspected or physically cleaned without specialized equipment, creating an environment where contaminants and bacteria can accumulate over time, unnoticed and unchecked, and solids accumulate, reducing flow and causing blockages.

Linear drain systems, on the other hand, are designed in a way that reduces the need for extensive underground piping, making drainage channels significantly easier to access for cleaning and maintenance. For instance, in the same 4,800-sq.-ft. facility, a linear system with a 100-ft. slot drain would require just 10 ft. of underground piping. This substantial reduction in buried infrastructure simplifies inspections and maintenance, enabling staff to efficiently keep the drainage system in optimal condition. Area drains demand a costly and complex four-slope floor design around each drain. In our example, this requires a total of 48 individual slopes, compared to only four for a linear drain system. Besides the higher construction costs and added complexity, this design creates uneven floor surfaces, reducing both efficiency and safety for workers and wheeled equipment.

Cleanability: grated drains vs. slot drains

Linear drains come in two primary forms: grated drains and slot drains. While both provide access to the drainage channel for cleaning, their designs differ significantly. Grated drains use removable grates to cover the channel, while slot drains offer a narrow, open, and sleek design that eliminates the need for a grate altogether.

Grated drains serve their purpose but can be problematic maintenance wise. Image provided by Global Drain Technologies

Grated drains have their place but come with their own set of issues. They can trap bacteria, leading to unpleasant odors and a higher risk of contamination. Cleaning them is a labor-intensive, time-consuming task due to the heavy, cumbersome grates, which can be difficult to handle. During cleaning, the uncovered drains pose a safety hazard, requiring sections of the area to be blocked off, causing interruptions and costly production downtime.

Over time, grated systems present further issues. The grates can rust or crack, becoming tripping hazards and compromising workplace safety. Many older drainage systems were not built to withstand the weight of modern, heavy machinery, such as autonomous material-handling equipment. This often results in warped grates, which not only endanger workers but also damage wheeled equipment that relies on smooth, even surfaces for maximum performance and durability.

Comprehensive portfolio of solutions

Effective drainage design goes beyond choosing the right drain type. Drainage system providers must offer a comprehensive portfolio of products and technologies tailored to the needs of food production facilities.

Companies like FoodSafe Drains, who provide whole-building drainage solutions, offer a well-rounded range of essential components like grates, catch basins, tamper-proof magnetic strainers, and high-quality sealing systems, as well as cleaning accessories like the Slot Dog and Slot Hog, to create an extensive collection of solutions. FoodSafe Drains products create a complete, high-performing system for the whole facility that is easy to maintain and meets the strict standards of food-safe environments.

Engineering for hygiene: designing drains that work

Another critical aspect of a whole-building approach is designing drains with built-in hygiene solutions. Modern slot drains, for example, address several of the key issues found in traditional drainage systems:

● Cleanability: Slot drains are designed for easy access and cleaning. Unlike traditional drains, which hide contaminants in underground pipes, slot drains allow for direct visual inspection and manual or automated flushing.

● Bacteria prevention: Because they eliminate the need for grates, slot drains remove common bacterial hotspots where contaminants can accumulate.

● Structural efficiency: Traditional area drains require a complex four-slope floor design, making installation costly and increasing the risk of uneven surfaces. Slot drains, by contrast, need only a single slope, reducing construction costs and improving floor safety.

One of the latest advancements in drainage hygiene is the introduction of secondary locking strainers. Traditional strainers are often removed and discarded by employees to avoid the hassle of cleaning them. This bad practice allows solids to enter underground piping, creating blockages and contamination risks. In contrast, secondary locking strainers prevent improper removal, ensuring proper maintenance practices are followed.

Proactive food safety: looking beyond the surface

Food manufacturing facilities are under increasing scrutiny for foodborne illness prevention, with recent outbreaks, such as 2024's Listeria outbreak, tied to contaminated production environments. A proactive approach to food safety means addressing all potential sources of contamination, including drainage.● Prevention over reaction: Instead of responding to contamination incidents, facilities should design their infrastructure to prevent bacterial growth in the first place.

● Regulatory compliance: As food safety regulations evolve, manufacturers that invest in hygienic drainage systems will be better equipped to meet and exceed compliance standards.

● Long-term cost savings: Upgrading to modern, low-maintenance drainage solutions reduces ongoing labor costs, minimizes downtime for cleaning, and extends the lifespan of facility infrastructure.

Adopting a whole-building approach to drainage is not merely an upgrade, but a transformative shift in food safety strategy. By integrating smart, hygienic drainage solutions across facilities, manufacturers can significantly reduce contamination risks, streamline maintenance processes,and ensure compliance with evolving food safety regulations. This approach is crucial for ensuring safety, preventing contamination, and optimizing efficiency in food production operations.

A thoughtfully engineered drainage system, tailored to meet the unique demands of each facility, delivers reliable performance even under challenging conditions. By proactively addressing hidden risks within the drain system, advanced drainage solutions enable safe, efficient operations while safeguarding productivity and regulatory compliance. Investing in innovative drainage technologies today paves the way for a safer, more efficient food production environment in the future.