This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Eagle Product Inspection, a provider of advanced inspection and product safety solutions, announces its RMI3/M x-ray inspection system, providing superior contaminant detection for high-volume bulk meat applications. Designed to meet the strict standards required for machine construction and sanitation in the red meat industry, the RMI3/M x-ray system inspects unpackaged bulk raw beef, pork, lamb, and similar products for contaminants such as metal, glass, stone, and calcified bone.

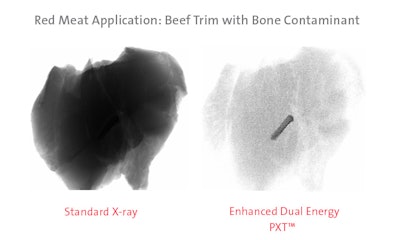

Equipped with PXT™, Eagle’s high-performance dual-energy x-ray technology, the RMI3/M x-ray system offers 100% inspection coverage for contaminants in unpackaged bulk raw meat, delivering peace of mind to manufacturers and consumers alike. Dual-energy technology enables red meat processors to obtain high-resolution images and capture detailed data about the product being inspected. The RMI3/M x-ray system provides the industry’s highest level of inline, automated bone detection while simultaneously performing product quality and integrity checks. Accurate weight calculations prevent costly product giveaway and statistics for mean value correction and giveaway calculations are actively tracked to optimize production efficiencies.

The RMI3/M x-ray system has an IP69 ingress protection rating, offering unimpeded sight lines for extensive visual inspection. Its design features minimal contoured surfaces, aiding in reduced material harborage points. Integrating proven design principles from respected industry authorities such as NAMI, NSF, and ANSI, the entire machine can be disassembled by a single person in a matter of minutes for thorough sanitation and quick reassembly to maximize production uptime. The system meets the criteria for Category 3 (EN954) and Performance Level “d” (PLd, EN13849) safety circuits, including full visualization, in the user interface, of the safety system status for the operator.

The RMI3/M x-ray system features SimulTask™ PRO advanced imaging and processing software that provides high resolution and extraordinarily detailed x-ray images with the highest grayscale range from 0-65,535. Manufacturers and further processors will see increased detection accuracy and significantly reduced false rejects. Eagle Repository™ is supplied as a standard that provides a simple way of storing, viewing, and transferring production information such as statistics, event logs, manually saved images, and reject images to other devices for storage. The optional Eagle TraceServer™ x-ray software program records valuable production data and machine status information from one or more of Eagle’s x-ray machines and consolidates it into a single centralized database.