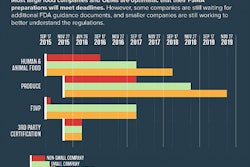

The first major compliance date for the Food & Drug Administration’s Food Safety Modernization Act (FSMA) occurred on September 19, 2016. It requires large manufacturers of human and animal food to meet preventive controls and Current Good Manufacturing Practice (CGMPS) requirements. That means having a safety system in place that includes an analysis of hazards and risk-based preventive controls.

In order to meet these requirements, the FDA has recommended that food companies set up a thorough system for documenting what they do in order to demonstrate they are meeting the legal criteria. In addition, companies are required to put processes and procedures in place that prevent problems in the first place.

The good news is, the majority of companies are ready to show an FDA agent that they are—and will—comply with the current and future food safety regulations. According to an Automation World survey, 74 percent of respondents said they are on track to meet FSMA requirements around preventive controls for food safety, sanitary transportation and foreign supplier verification programs. The majority of companies (86.5 percent) are meeting this first compliance requirement mainly because they already have a Hazard Analysis and Critical Control Points (HACCP) plan in place, a food safety management system that has similar preventive control rules.

Key to HACCP enforcement—like FSMA compliance—is documentation, and 70.3 percent of respondents said they use a document management system to identify possible hazards in the food production process. The other technologies companies said they have in place as part of their HACCP plan include quality management systems (85.6 percent), a historian database (53.2 percent) enterprise resource planning (42.3 percent). Additional technologies in use include sensors and intelligent algorithms (35.1 percent) and food production management software (28.8 percent).

Technology is a critical factor in FSMA, so it’s no surprise that the biggest obstacle to compliance is new technology investments and implementation, followed by data management and analysis, and the lack of skills and resources. “We are constantly improving our data management and analysis, accurate record keeping, quality control and training,” said one survey respondent.

In addition, manufacturers are also keeping close tabs on the supply chain—the survey results show that a full 92 percent of manufacturers are tracking products and materials through the supply chain. Unfortunately, there’s still some work to be done, as 55 percent said supply chain traceability is done “fairly well, but needs some improvement.” Another 28 percent consider their supply chain management as “best in class,” meanwhile, 13.5 percent said they require complete new processes to do this, and the remaining respondents don’t track the supply chain at all.

For those companies that have supply chain visibility, the majority (70 percent), said that bar codes are their best friends. A small group (20 percent) are even adopting serialization technology as outlined by the Drug Supply Chain Security Act (DSCSA).

So, of course, at the end of this survey, we had to ask food and beverage manufacturers what it was that keeps them up at night. Here’s a short list of some of the most common responses (in no particular order):

- Recalls

- Cost to implement technology

- Ensuring 24x7 compliance

- Quality control

- Staff shortages/talent acquisition

- Traceability

- Documentation

- Security

- Safety

- Downtime

- And, just keeping up with changing regulations of the FDA.

The FDA understands that this is new territory for the food and beverage industry. In a recent article on the FDA website, Joann Givens, co-chair of the FSMA Operations Team Steering Committee, said the FDA’s primary focus going forward will be on continuing education, training and technical assistance to help companies comply with new requirements. But, she cautions, that doesn’t mean that companies won’t be held responsible if they don’t meet the new standards. “The FDA’s mandate is to protect public health and, when necessary, the agency will act swiftly,” she said.