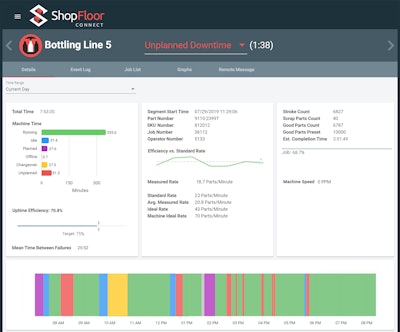

Wintriss Controls Group, a manufacturer for the metal stamping industry and discrete manufacturing, has developed its ShopFloorConnect OEE, a Shop Floor Data Collection Software, which collects downtime and production efficiency data from every machine in the manufacturing operation, displays it in real-time, and produces manufacturing reports—including detailed OEE reports in a variety of formats. The software is designed to increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks.

The companys says the ShopFloorConnect Version 6.0 design format has fast and easy access to all data, and offers several features for robust, user-friendly reporting and dashboard customization, flexible scheduling capabilities, and machine interface enhancements, all of which affect OEE. Users can also track the reasons for scrap through the software to improve their machine’s OEE. Version 6.0 is further designed to allow users to manually enter good and bad part count data for OEE calculation when machines with batch processes make it impossible or impractical to automatically count the parts as they are being produced.

Enhanced user interfaces and scheduling capabilities are also available in ShopFloorConnect Version 6.0. Users such as production supervisors, manufacturing engineers, and job schedulers with different information requirements, can customize the way data are displayed on their dashboards. The software is also designed for flexible scheduling to enable the next five jobs to be sent to the ShopFloorConnect Machine Interface (SMI-2), so users can view and switch to other high-priority jobs in the event that unforeseen circumstances prevent starting the highest priority job.