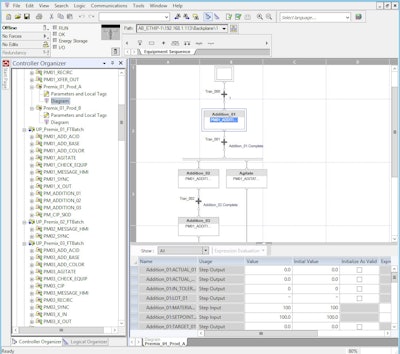

Using a Logix-based controller platform, the software allows operators to configure, view and obtain critical information about batch sequences stored in the controller, increasing visibility and accessibility to all stages of the production process. Modern interfaces, workflows and accessibility features enable operators to focus on production needs instead of managing system navigation and manual interventions, and view standardized batch reporting for seamless integration with other company products. Highly scalable architecture allows OEMs to develop, test and deliver skids as fully functioning, standalone equipment that can seamlessly integrate into a site’s existing batch strategy without the need to redeploy the code. End users will realize efficiencies in integration and reduced infrastructure costs that traditional batch solutions may normally require. Placing the recipe and sequencing in the controller enables the SequenceManager solution to control high-speed and time-dependent processes through rapid response and secured connectivity. The software is suitable for such industries as food, beverage, pharmaceutical and chemical. Specific applications include single- or multiple-independent unit operations, such as OEM skids, clean-in-place systems, dryers, evaporators, ovens and reactors.