This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

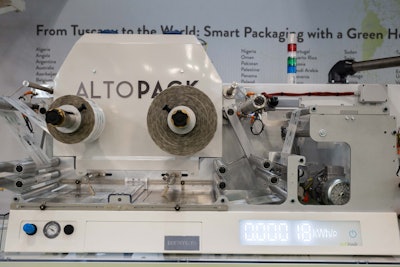

The new AOD Ultra is part of the EcoFriendly line, Altopack’s portfolio of machines designed to maximize efficiency and reduce environmental impact, confirming the company’s commitment to increasingly sustainable production.

A complete line, live in action

During the Milan fair, the new AOD was showcased as an integral part of a complete long pasta packaging line, fully operational and running in real production conditions. This live demonstration highlighted the machine’s reliability and capabilities in an industrial setting, allowing visitors to concretely appreciate its performance.

Ultrasound for more efficient sealing and zero waste

Altopack proved that choosing environmentally friendly solutions can be economically advantageous, dispelling the common misconception that climate action measures offer no additional benefits.

The new machine sets new standards in energy savings, film consumption, and product waste reduction.

Among the main innovations, the replacement of all heating elements with a new cold sealing system stands out, reducing power consumption by about 70%. The ultrasonic longitudinal and transverse sealing devices allow a reduction in the film band and cutting pitch, saving over 20 tons of film annually. Furthermore, the system’s precision ensures no waste after stoppages and prevents pasta fragments from being trapped in the seals, eliminating the risk of defective packages and contributing to a leaner and more sustainable production process. It also enhances worker health and safety by eliminating the risk of accidental burns.

Objective measurement, in real time

Altopack emphasizes transparency. For this reason, the new AOD Ultra can be equipped with the EcoFriendly Display, a practical and elegant device that measures the machine’s carbon footprint in real time during the production cycle. This is a concrete tool to monitor and communicate environmental impact, designed both for operators and companies committed to sustainability. This is not greenwashing, but an approach based on measurable and verifiable data.

In addition to the new features, the AOD Ultra retains the characteristics that made it a benchmark for long pasta packaging. Efficient, it combines ease of use with high performance. Technological, it can be equipped with the latest smart devices: zero air device, cameras for package inspection and printing, stripping system, and much more. Versatile, it integrates with various weighing systems, offering customized solutions for every production need.

With the new AOD Ultra, Altopack confirms its ability to innovate within the tradition of Italian industry, while paying close attention to market and environmental needs. This machine is not only a technical evolution but also a concrete sign of how sustainability and performance can coexist in the factory of the future.