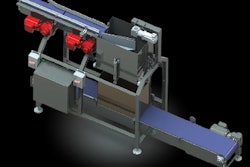

Perhaps best known for a variety of canning and food processing technologies, Solbern recently unveiled a roll-fed wrapping and labeling machine for subs and other hand-held foods. It’s available in either single- or twin-station formats, depending on the customer’s output requirements. The machine shown here has two wrapping stations; a single operator picks a submarine-style sandwich from an infeed conveyor and places it into one wrap station and then the other. A Leuze photoeye signals the Rockwell PLC that a sandwich is present and the PLC activates the wrapping sequence. Also important to point out is that Keyence light curtains ensure that only after the operator’s hands are safely out of harm’s way can the wrapping sequence be activated.

In each wrapping station there are four stepper motors. Two HW24-108 steppers are for the side grippers that assist in rotating the sandwich/food product. One HW34-696 stepper is for the roller assembly that rolls the product during the wrapping sequence. The last stepper, another HW34-696, drives the nip roller assembly. Each of the stepper motors, which come from Applied Motion, is governed by its own Applied-Motion ST5-IP-EN programmable drive.