Source: 2017 Global Packaging Trends produced by Euromonitor International and PMMI, The Association for Packaging and Processing Technologies.

Latin America’s weak economy means overall packaging growth will be slow in the region, but flexible plastic packaging will be able to thrive due to its affordability and convenience, according to the 2017 Global Packaging Trends report from Euromonitor International and PMMI, The Association for Packaging and Processing Technologies.

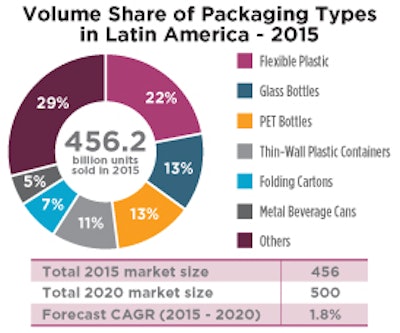

The report forecasts only a 1.8 percent compound annual growth rate in packaging from 2015 to 2020 in Latin America. However, flexible plastic packaging will grow because it is lightweight, recyclable, inexpensive and meets the increasing demand for packaged foods, according to the report.

Companies in this article